Confocal Noncontact Measuring System

Confocal Noncontact Measuring System

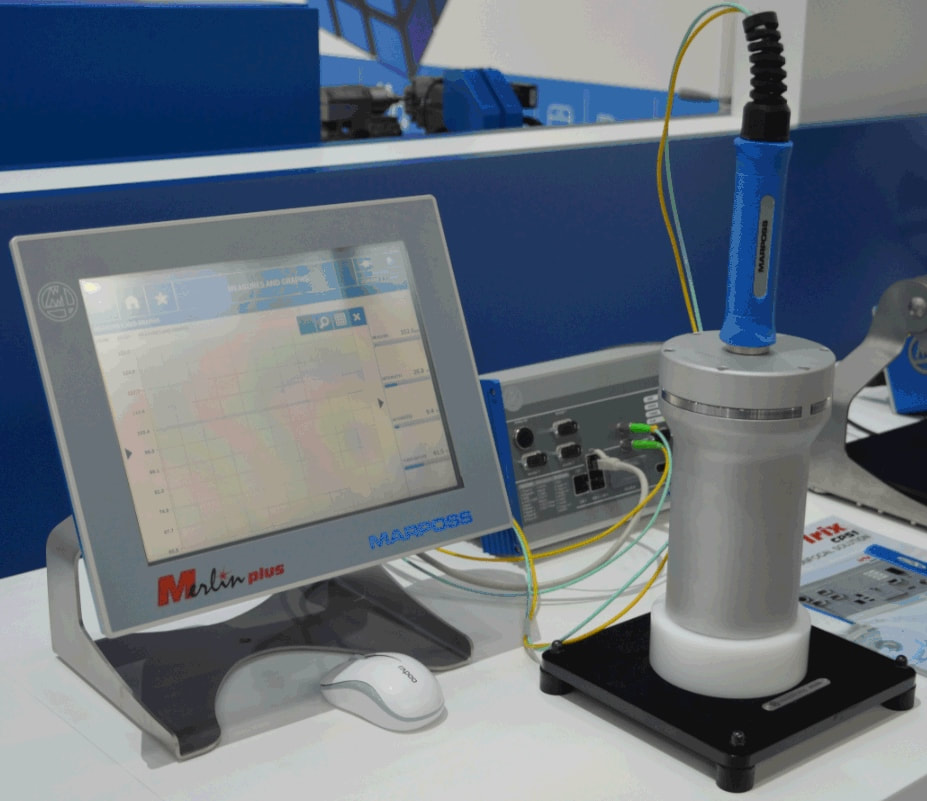

Marposs announces the availability of Confocal, a noncontact measuring system that enables very fast, high resolution distance and thickness gauging of almost any surface including solid, transparent and polished mirror surfaces such as glass, plastic or silicon wafers. Featuring a 4mm optical sensor within the measuring probe, the accuracy is extremely precise, enabling the identification of very small aberrations in shape, air gap or paint finish.

Marposs announces the availability of Confocal, a noncontact measuring system that enables very fast, high resolution distance and thickness gauging of almost any surface including solid, transparent and polished mirror surfaces such as glass, plastic or silicon wafers. Featuring a 4mm optical sensor within the measuring probe, the accuracy is extremely precise, enabling the identification of very small aberrations in shape, air gap or paint finish.

The measuring probe placement can be adjusted to achieve high accuracy. For example, a measuring range of 0.4 mm provides 0.055 µm accuracy whereas a measuring range of 12 mm provides about 0.750 µm accuracy. Example applications include:

- Detection of metal burrs in cell phone holes

- Measurement of air gaps between two pieces of glass being assembled into a windshield

- Thickness measurement of transparent finishing paint on a glass surface

- Diameter measurement of plastic insulin syringe fingers

Marposs offers the solution with different sensor models and either a DIN rail controller for combination with a PC or a stand-alone unit with an integrated 7-inch display screen.

The Confocal solution is based on the confocal chromatic measuring principle, where white light is split into different spectra using lenses focused on an object through a multiple-lens optical system. The lenses are arranged to create and send a chromatically aberrated beam to the target. The target reflects the optical beam back to the probe where it transmits the reflected optical beam to a spectrometer. The reflected optical beam is comprised of rays coming from the outside surface of the object being measured and from the internal surfaces that the beam is able to reach.

The reflected light intensity is at a maximum for the wavelengths focused on the surfaces. Electronic processing can then determine the intralayer thickness values of the target, or the distance from the probe to the outside surface and to the intralayer surfaces of the target.