Contact Details

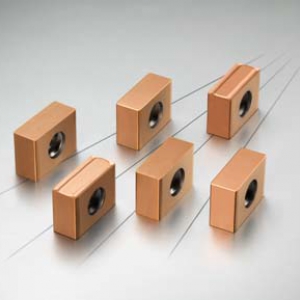

The new CoroMill Plura compression end mill for composites from Sandvik Coromant is certain to be of great interest to any manufacturer machining carbon-fiber reinforced polymers. The innovative CoroMill Plura tool combines positive and negative helix design to "compress" the top and bottom of the component edge. This minimizes any potential for delamination, a common defect when machining CFRP and several other types of engineering composites using higher helix cutters.

The new Plura end mill has been designed for edge milling applications on workpieces with a minimum thickness of 6mm. It features optimized micro geometry that offers six effective cutting edges for achieving a surface finish (Ra) of well below 0.0001" (4µm), in combination with high material removal rates. Users should keep the split-line in the middle of the material for best results. Also, remember that when the tool cuts fibers going against the grain on the top or bottom surface there is potential for more splintering than when the tool cuts along the fiber direction.

Conventional up-milling strategies are recommended as these typically deliver less vibration. Among the cutting data users can expect to see is cutting speeds of 656-1312 ft./min. (200-400 m/min), and feed rates of 0.001-0.002"/tooth (0.03-0.06mm/tooth) for roughing or 0.008-0.0015"/tooth (0.02-0.04mm/tooth) for finishing.

Aside from the aerospace industry, other sectors set to benefit from the new end mill include motorsport, marine, wind energy and leisure, essentially any company machining CFRP that is looking to enhance material removal rate and tool life while at the same time achieving minimal delamination of layers.

The CoroMill Plura compression end mill for composites makes use of GC1630 grade for extended life, and comes in diameters ranging from 0.24-0.63" (6.0-16.0mm), and lengths (total) from 2.99-3.94" (76 to 100mm).

Related Glossary Terms

- composites

composites

Materials composed of different elements, with one element normally embedded in another, held together by a compatible binder.

- feed

feed

Rate of change of position of the tool as a whole, relative to the workpiece while cutting.

- gang cutting ( milling)

gang cutting ( milling)

Machining with several cutters mounted on a single arbor, generally for simultaneous cutting.

- milling

milling

Machining operation in which metal or other material is removed by applying power to a rotating cutter. In vertical milling, the cutting tool is mounted vertically on the spindle. In horizontal milling, the cutting tool is mounted horizontally, either directly on the spindle or on an arbor. Horizontal milling is further broken down into conventional milling, where the cutter rotates opposite the direction of feed, or “up” into the workpiece; and climb milling, where the cutter rotates in the direction of feed, or “down” into the workpiece. Milling operations include plane or surface milling, endmilling, facemilling, angle milling, form milling and profiling.

- milling machine ( mill)

milling machine ( mill)

Runs endmills and arbor-mounted milling cutters. Features include a head with a spindle that drives the cutters; a column, knee and table that provide motion in the three Cartesian axes; and a base that supports the components and houses the cutting-fluid pump and reservoir. The work is mounted on the table and fed into the rotating cutter or endmill to accomplish the milling steps; vertical milling machines also feed endmills into the work by means of a spindle-mounted quill. Models range from small manual machines to big bed-type and duplex mills. All take one of three basic forms: vertical, horizontal or convertible horizontal/vertical. Vertical machines may be knee-type (the table is mounted on a knee that can be elevated) or bed-type (the table is securely supported and only moves horizontally). In general, horizontal machines are bigger and more powerful, while vertical machines are lighter but more versatile and easier to set up and operate.

PRODUCTS

PRODUCTS