Contact Details

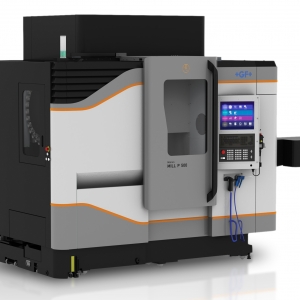

GF Machining Solutions says its new AgieCharmilles CUT P Series of wire EDMs provides users precise positioning and contouring capabilities for enhanced part quality and productivity. The CUT P 350/550/800/1250 machines feature efficient power generators, robust designs and intuitive human-machine interfaces (HMIs), as well as several automation options for lights-out operation.

With Intelligent Power Generator (IPG) technology, CUT P Series machines deliver surface finishes as smooth as Ra 0.10 µm and boost cutting speeds by up to 20 percent. Several EXPERT systems further optimize the IPG’s cutting performance, especially for challenging applications.

POWER-EXPERT monitors and smoothly changes power levels while the machine cuts parts with variable heights. The system protects the parts from unstable conditions while the machine maintains high cutting speeds. Simultaneously, SURFACE-EXPERT controls the spark parameters during finish operations to provide high-quality surface finishes on variable-height parts. This maximizes part finishes and significantly reduces the need for secondary benchwork.

Regardless of workpiece height, WIRE-EXPERT dynamically controls wire wear to achieve continuous geometrical accuracy from all directions. For part profile accuracy, PROFIL-EXPERT automatically adapts the machining parameters and the cut path for rough and skim passes to provide excellent control of fine details and to ensure positioning and contour accuracies of ±2 µm, while TAPER-EXPERT technology cuts angles from 0 to 30 degrees (45 degrees as an option) to maximum Z heights.

TAPER-EXPERT corrects shifts of the Z reference position in real time, even when the taper angle is changing. The taper angle is also held to within 10 seconds on average, providing taper accuracy and geometry reference accuracy throughout the taper cut.

Fixed tables on CUT P Series machines provide rigidity and stability that ensure accuracy when machining heavy workpieces. Integrated temperature regulation systems consistently maintain temperatures within ±0.2 degrees Celsius, which guarantees repeatability over long periods of time. However, in shops where the ambient temperature may vary throughout the day, a Thermostability option provides an extra layer of temperature control protection from thermal effects on machine axes.

The machines also feature GF Machining Solutions’ unique collision protection technology in the X, Y, U, V and Z axes that prevents potential machine damage and eliminates costly down time and maintenance, even at maximum axis travel speeds of 3 m/min.

The Windows 7-based AC CUT HMI 2 user interface on CUT P Series machines simplifies file management and maximizes operator efficiency with its 19" touch screen and today’s i7 CPU technology. AC CUT HMI 2 also supports intuitive programming directly on the control, as well as imported CAD/CAM files with built-in AC CAM EASY CAD/CAM software. The CUT P Series is also ready for the Internet of Things/Industry 4.0 with eConnectivity features that connect the machine to larger shop management systems for effective monitoring and increased machine utilization.

New automation solutions, including Automatic Slug Management (ASM), Automatic Slug Welding (ASW) and Renishaw probing system, reduce processing time by up to 20 percent in lights-out production environments. Additionally, the CUT P Series 350 and 550 can integrate with robots such as the System 3R WorkPartner 1+ that automatically loads and unloads parts for a single machine or within a two-machine automation cell that doubles machine production capacities.

With over 600 dedicated, pre-programmed cutting processes, the CUT P Series machines optimize production for electronics, automotive, medical and mold and die manufacturers. The series tackles parts ranging from less than 1 mm up to 800 mm in height, weighing up to 6,000 kg made of a host of materials from steel, carbide and copper to aluminum, titanium and graphite. Wires are available in 0.1 mm, 0.15 mm, 0.2 mm, 0.25 mm, 0.3 mm and 0.33 mm diameters.

Related Glossary Terms

- computer-aided manufacturing ( CAM)

computer-aided manufacturing ( CAM)

Use of computers to control machining and manufacturing processes.

PRODUCTS

PRODUCTS