D-2 Air Hardening Tool Steel

D-2 Air Hardening Tool Steel

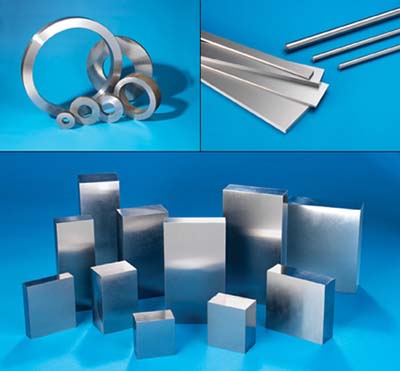

D-2 air hardening tool steel from Diehl Steel is available in flats, hollowbar, rounds, squares, metric and standard forms.

D-2 air hardening tool steel from Diehl Steel is available in flats, hollowbar, rounds, squares, metric and standard forms. It is a versatile high-carbon, high-chromium, air-hardening tool steel characterized by a relatively high attainable hardness and numerous, large, chromium rich alloy carbides in the microstructure. These carbides provide good resistance to wear from sliding contact with other metals and abrasive materials.

Diehl Steel's D-2 tool steel provides an effective combination of wear resistance and toughness, tool performance and price. Diehl can machine D-2 tool steel to toolmaker tolerances using its Accu-Square process, and typically ships in-stock orders in 24 to 48 hours.