Contact Details

Tungaloy’s DeepTri-Drill line of indexable deep-hole drills now includes FH3135-grade guide pads.

DeepTri-Drill is a successful line of indexable insert gun drills that provides productivity and application security for drilling deep holes, while ensuring easy tool management by eliminating the need for regrinding. The drill line now offers a new FH3135-grade guide pad that was developed specifically to enhance thermal crack resistance when machining with water emulsifiable oils.

The tribological conditions during gun drilling between the guide pad surfaces and the wall of the hole being drilled are far more severe than those during other applications. To ease this harsh condition and maximize guide pad life, it is crucial to use cutting fluids with high lubricity in order to prevent dry rubbing and seizure at the burnishing contact areas. For these reasons, straight cutting oils have long been preferred among manufacturers in gundrilling operations for its high lubricity. However, in today’s environmental conscious machining, the call for eco-friendly water emulsifiable oils, more commonly known as soluble oils, are increasing over conventional petroleum-based coolants. These soluble oils have lower lubricity than straight oils and can adversely affect the guide pad quality during gundrilling.

To meet this challenge, Tungaloy has expanded its DeepTri-Drill guide pad options to include the FH3135 grade. Guide pad rupture is primarily induced by an increase in density of thermally-induced microcracks generated on the substrate due to poor lubricity and thermal capacity when machined with soluble oils. The dedicated carbide substrate of the FH3135 guide pad provides enhanced resistance to fracture and thermal crack, significantly reducing the risk of guide pad breakages. In addition, the new guide pad features a double-chamfer geometry on the corners of both ends assisting a smooth entry into the guide bushing or pilot hole, inherent when machining on dedicated gundrilling machines. This reduces vibrant impact on the guide pads and the risk of rupture.

At a glance:

Guide pads with high fracture resistance for use with soluble oils

Dedicated carbide substrate has superior resistance to fracture and thermal cracks

Double-chamfer geometry allows smooth entry into a guide bushing or pilot hole

Total of 13 items to be added

Related Glossary Terms

- burnishing

burnishing

Finishing method by means of compressing or cold-working the workpiece surface with carbide rollers called burnishing rolls or burnishers.

- bushing

bushing

Cylindrical sleeve, typically made from high-grade tool steel, inserted into a jig fixture to guide cutting tools. There are three main types: renewable, used in liners that in turn are installed in the jig; press-fit, installed directly in the jig for short production runs; and liner (or master), installed permanently in a jig to receive renewable bushing.

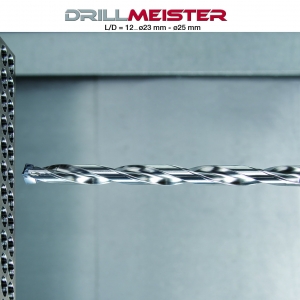

- gundrilling

gundrilling

Drilling process using a self-guiding tool to produce deep, precise holes. High-pressure coolant is fed to the cutting area, usually through the gundrill’s shank.

- indexable insert

indexable insert

Replaceable tool that clamps into a tool body, drill, mill or other cutter body designed to accommodate inserts. Most inserts are made of cemented carbide. Often they are coated with a hard material. Other insert materials are ceramic, cermet, polycrystalline cubic boron nitride and polycrystalline diamond. The insert is used until dull, then indexed, or turned, to expose a fresh cutting edge. When the entire insert is dull, it is usually discarded. Some inserts can be resharpened.

- lubricity

lubricity

Measure of the relative efficiency with which a cutting fluid or lubricant reduces friction between surfaces.

PRODUCTS

PRODUCTS