Contact Details

Tungaloy has upgraded its MiniForceTurn by introducing thirty new DXGQ/U0703.. inserts with brazed CBN tips and HP chipbreaker. This upgrade will boost productivity in hard part turning applications. The CBN inserts will now be sold in newly designed boxes containing five inserts each.

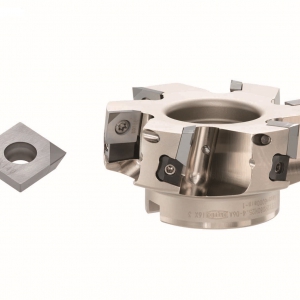

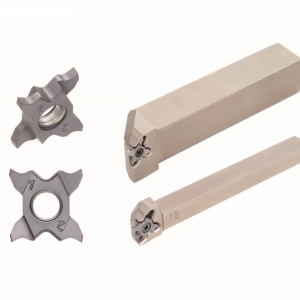

MiniForceTurn turning tool series offers double-sided turning inserts with positive rake cutting edges on both sides. These inserts enable free cutting action like that of positive inserts with an added advantage of double cutting edges.

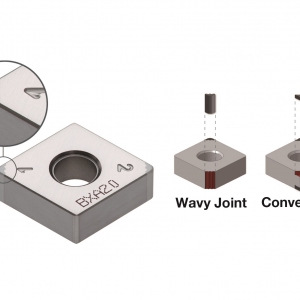

The new DXGQ/U0703.. inserts feature 55° nose angle with brazed CBN tips that are designed for hard part turning applications. The inserts incorporate HP chipbreaker and use WavyJoint brazing technology for the CBN tips which are designed to provide enhanced insert reliability during hard part turning. Also, the inserts feature four total cutting edges for excellent cost-per-part efficiency.

The inserts are available in three coated-CBN grades; namely, BXA10, BXA20, and BR35F, which cover an application range from continuous to interrupted cuts.

The new DXGQ/U0703.. CBN inserts fit the existing toolholders: SDXXR/L style toolholders for internal profiling and SDZXR/L style toolholders for internal back spot facing. With the proven effectiveness of the existing WXGQ/U0403.. CBN insert line, the enhanced MiniForceTurn CBN inserts will contribute to productivity boost for the users involved in internal turning applications of hardened steel parts.

Related Glossary Terms

- chipbreaker

chipbreaker

Groove or other tool geometry that breaks chips into small fragments as they come off the workpiece. Designed to prevent chips from becoming so long that they are difficult to control, catch in turning parts and cause safety problems.

- cubic boron nitride ( CBN)

cubic boron nitride ( CBN)

Crystal manufactured from boron nitride under high pressure and temperature. Used to cut hard-to-machine ferrous and nickel-base materials up to 70 HRC. Second hardest material after diamond. See superabrasive tools.

- profiling

profiling

Machining vertical edges of workpieces having irregular contours; normally performed with an endmill in a vertical spindle on a milling machine or with a profiler, following a pattern. See mill, milling machine.

- rake

rake

Angle of inclination between the face of the cutting tool and the workpiece. If the face of the tool lies in a plane through the axis of the workpiece, the tool is said to have a neutral, or zero, rake. If the inclination of the tool face makes the cutting edge more acute than when the rake angle is zero, the rake is positive. If the inclination of the tool face makes the cutting edge less acute or more blunt than when the rake angle is zero, the rake is negative.

- turning

turning

Workpiece is held in a chuck, mounted on a face plate or secured between centers and rotated while a cutting tool, normally a single-point tool, is fed into it along its periphery or across its end or face. Takes the form of straight turning (cutting along the periphery of the workpiece); taper turning (creating a taper); step turning (turning different-size diameters on the same work); chamfering (beveling an edge or shoulder); facing (cutting on an end); turning threads (usually external but can be internal); roughing (high-volume metal removal); and finishing (final light cuts). Performed on lathes, turning centers, chucking machines, automatic screw machines and similar machines.

PRODUCTS

PRODUCTS