ErgoFlex Abrasive Disc

ErgoFlex Abrasive Disc

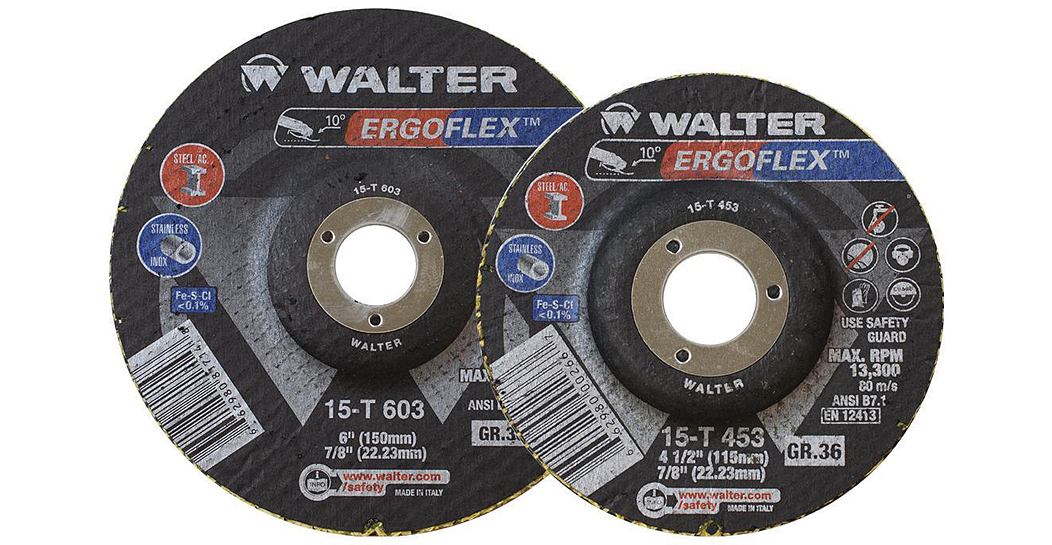

Walter Surface Technologies has unveiled its new ErgoFlex abrasive disc—a safer, more ergonomic, equally powerful alternative to traditional grinding wheels. Combining a type 29 disc design and Walter's proprietary Cyclone technology, ErgoFlex is for extremely smooth weld blending on both flat and curved surfaces.

Walter Surface Technologies has unveiled its new ErgoFlex abrasive disc—a safer, more ergonomic, equally powerful alternative to traditional grinding wheels. Combining a type 29 disc design and Walter's proprietary Cyclone technology, ErgoFlex is for extremely smooth weld blending on both flat and curved surfaces. It allows for a more comfortable working angle than type-27 depressed center grinding wheels, along with cleaner, quieter grinding operations. With an aggressive 36 grit or higher abrasive grain blend, ErgoFlex removes material fast with minimal gouging risk.

"For manufacturing professionals looking to balance safety, ergonomics, and productivity, ErgoFlex is the perfect solution," says Marc Brunet-Gagné, product manager of bonded abrasives at Walter Surface Technologies. "ErgoFlex offers the same power and speed as traditional grinding wheels, but with 95 percent less dust, 50 percent less noise, 50 percent less vibrations and better ergonomics. It's also less likely to gouge materials, thus increasing efficiency and cost savings."

Designed for heavy manufacturing, pipeline construction, metal fabrication, and other industrial needs, ErgoFlex is suitable for use in a wide range of grinding operations including grinding welded steel and stainless steel, heavy grinding, weld removal and beveling.