Expanded Line of 335.25 Disc Mill Cutters

Expanded Line of 335.25 Disc Mill Cutters

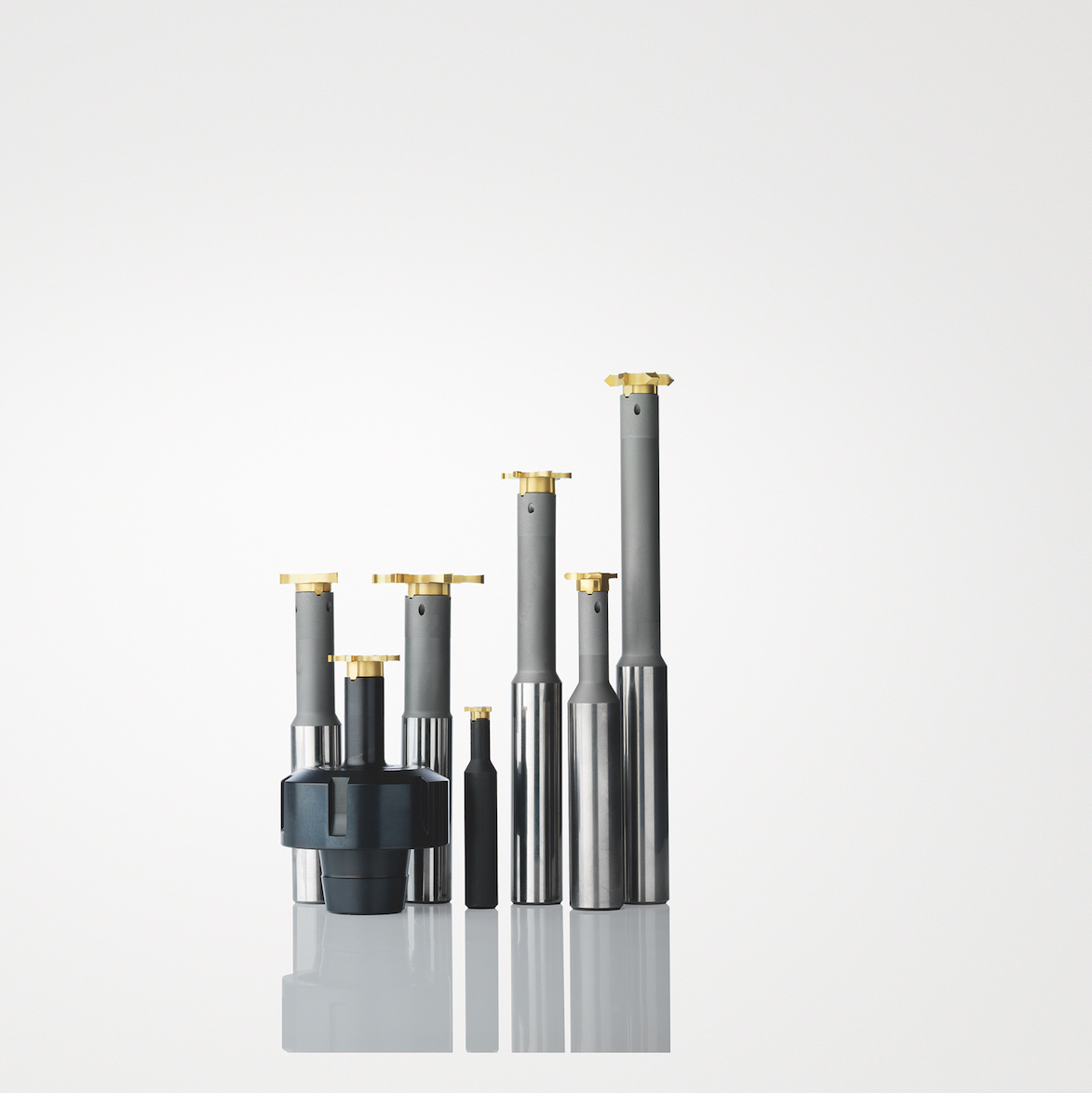

Seco has further expanded its selection of disc milling inserts and cutter bodies to meet customer demands for reliable, high performing cutters. With that, the company has introduced the 335.14 small-diameter exchangeable head system, 335.16 cutter for T-slot operations and cassette versions of its 335.25 cutter that incorporate round inserts.

Seco has further expanded its selection of disc milling inserts and cutter bodies to meet customer demands for reliable, high performing cutters. With that, the company has introduced the 335.14 small-diameter exchangeable head system, 335.16 cutter for T-slot operations and cassette versions of its 335.25 cutter that incorporate round inserts.

Using small-diameter exchangeable carbide heads, the 335.14 offers a versatile, precise cutting profile that easily tackles any type of material, according to the company. These cutters are ideal for groove milling, circlip grooves, full radius profiles, threading profiles and chamfering. Reliable exchangeable head systems control machining costs, and the 335.14 product line comes in a variety of cylindrical and integrated collet chuck shanks in diameters from 0.38" (9.7 mm) to 1.37" (34.7 mm) that cut widths from 0.03" (0.74 mm) to 0.207" (5.26 mm.)

Seco's stable 335.16 cutters incorporate four-edged inserts to economically perform demanding T-slot operations. Modern insert geometries reduce machining forces and noise for optimal tool life. Centralized cooling channels effectively remove chips and provide excellent surface finishes and finished part quality. Cutters come in diameters from 0.97" (25 mm) to 1.844" (50 mm) based on standardized T-slot dimensions. The expansive selection of insert geometries and grades cut many materials in widths ranging from 0.39" (11 mm) to 0.82" (21 mm.)

The expanded line of 335.25 disc mill cutters includes new cassettes for 0.63" (16-mm) and 0.79" (20 mm) round insert diameters. These cutters perform well in various full side, face or half side and face operations for applications involving corner radii. The exchangeable cassettes ensure long, reliable cutter performance, while the large choice of insert geometries and grades provide freer cutting operations and increase cost-efficiency in any type of material. Cutter diameters for these new sizes range from 4.00" (100 mm) to 12.00" (315 mm.)