Contact Details

WALTER, a brand of UNITED GRINDING, introduces the new HELITRONIC MINI PLUS. Whether producing complete tools or regrinding, the new HELITRONIC MINI PLUS can fit your needs as a cost-effective basic machine or as a fully automated tool grinding system. "The basic version of the HELITRONIC MINI PLUS can be individually configured with numerous efficiency options and various loading systems - right up to a fully equipped high-end tool grinding machine for all current and future applications in the small and medium diameter range," explains Siegfried Hegele, Product Manager Applications at WALTER.

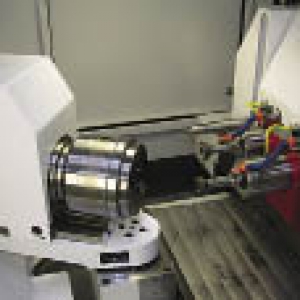

The basis for the extraordinary flexibility of the HELITRONIC MINI PLUS is the unique WALTER gantry design. The economical production of common and complex geometries of tools with a diameter range of 1mm - 16mm (0.04" - 0.63") in one clamping is guaranteed by the powerful HSK belt spindle with two spindle ends for up to six grinding wheels. In addition, the revolutionary C.O.R.E. hardware and software architecture with intuitive operation facilitates machine set-up, operation, networking and maintenance.

WALTER offers a wide range of options for the HELITRONIC MINI PLUS for application-specific configuration. These include, for example, an automatic grinding wheel changer for up to six grinding wheel holders (maximum diameter 152.4 mm [6”]) including coolant supply lines, which ensures a safe wheel set change and offers maximum flexibility. In addition, for machines equipped with the grinding wheel changer, a "torque increase" option is available which increases torque and removal rate by up to 60 percent, guaranteeing maximum productivity.

For the automation of the HELITRONIC MINI PLUS, users can choose between a top loader and a robot loader, with three different equipment packages, for even greater flexibility. The top loader integrated into the workspace is a space-saving and cost-effective automation solution. Depending on the tool diameter, it offers up to 500 tool locations. Using the robot loader, up to 7,500 tools can be loaded depending on the type of tools or tool diameter. The maximum tool weight is 11 pounds (five kg), the maximum diameter 4.9” (125 millimeters).

The HELITRONIC MINI PLUS uses the globally proven HELITRONIC TOOL STUDIO grinding software from WALTER, which offers simple programming with the greatest possible flexibility.

Related Glossary Terms

- coolant

coolant

Fluid that reduces temperature buildup at the tool/workpiece interface during machining. Normally takes the form of a liquid such as soluble or chemical mixtures (semisynthetic, synthetic) but can be pressurized air or other gas. Because of water’s ability to absorb great quantities of heat, it is widely used as a coolant and vehicle for various cutting compounds, with the water-to-compound ratio varying with the machining task. See cutting fluid; semisynthetic cutting fluid; soluble-oil cutting fluid; synthetic cutting fluid.

- grinding

grinding

Machining operation in which material is removed from the workpiece by a powered abrasive wheel, stone, belt, paste, sheet, compound, slurry, etc. Takes various forms: surface grinding (creates flat and/or squared surfaces); cylindrical grinding (for external cylindrical and tapered shapes, fillets, undercuts, etc.); centerless grinding; chamfering; thread and form grinding; tool and cutter grinding; offhand grinding; lapping and polishing (grinding with extremely fine grits to create ultrasmooth surfaces); honing; and disc grinding.

- grinding machine

grinding machine

Powers a grinding wheel or other abrasive tool for the purpose of removing metal and finishing workpieces to close tolerances. Provides smooth, square, parallel and accurate workpiece surfaces. When ultrasmooth surfaces and finishes on the order of microns are required, lapping and honing machines (precision grinders that run abrasives with extremely fine, uniform grits) are used. In its “finishing” role, the grinder is perhaps the most widely used machine tool. Various styles are available: bench and pedestal grinders for sharpening lathe bits and drills; surface grinders for producing square, parallel, smooth and accurate parts; cylindrical and centerless grinders; center-hole grinders; form grinders; facemill and endmill grinders; gear-cutting grinders; jig grinders; abrasive belt (backstand, swing-frame, belt-roll) grinders; tool and cutter grinders for sharpening and resharpening cutting tools; carbide grinders; hand-held die grinders; and abrasive cutoff saws.

- grinding wheel

grinding wheel

Wheel formed from abrasive material mixed in a suitable matrix. Takes a variety of shapes but falls into two basic categories: one that cuts on its periphery, as in reciprocating grinding, and one that cuts on its side or face, as in tool and cutter grinding.

Additional Products from United Grinding North America Inc.

Pagination

- First page

- Previous page

- 1

- 2

- 3

- 4

- 5

PRODUCTS

PRODUCTS