Contact Details

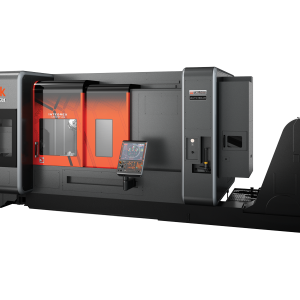

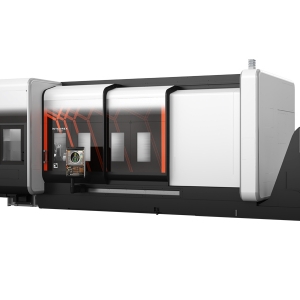

Mazak Corp. has introduced its new Mazatrol SmoothAi CNC, which is available on the Integrex i-450H S Multi-Tasking Machine. In addition to the control, the machine has a new design that increases flexibility and enhances machine performance for significantly easier automation integration, allowing shops to cost effectively boost the output of existing workforces.

As the newest CNC within Mazak’s Smooth Technology platform, the Mazatrol SmoothAi centers around three main function categories that are automation, digital machine twins and artificial intelligence (AI). Within its automation

function, the control includes Smooth Robot Cell Controller (RCC) and Smooth Robot Setup Assist, both of which make advanced robotic automation setup and operation with the Intregrex i-450H S fast and seamless.

Within the Mazatrol SmoothAi control, Mazak’s Mazatrol Twins software allows shops to create, on a PC, synchronized digital twins of real machines on their shop floors. The digital twins software solutions provide highly efficient machine operation through Smooth Project Manager that ensures efficient job setups and Smooth CAM Ai for an open and interactive interface for CAD/CAM software packages. For fully optimized machining operations, the AI technologies within the new Mazatrol SmoothAi control make for fast and easy programming, control spindle

speed for reduced vibration and boost thermal stability. These Mazak technologies include Solid Mazatrol, which allows users to automatically generate programs from 3D part models; Smooth Ai Spindle, which automatically optimizes spindle speed based on sensor feedback to minimize machining vibration for superior part surface

finishes; and Ai Thermal Shield, which adapts to and learns from environmental changes to control the effects of heat on machining accuracy.

Specific INTEGREX i-450H S machine changes that ease the integration of automation, include front and rear tool setup, flat front design to accommodate robots, tool magazine at the machine’s rear side and an easily retrofittable automatic machine door. Other new additions that make for easy machine automation are an integrated automatic jaw changer (AJC) and parallel-type lower turrets. Requiring no additional robot system and without interrupting machine operation, the AJC quickly exchanges jaws from turning spindle chucks with others in jaw stocker systems located above both of the machine’s turning spindles. These stocker systems have room for up to 10 jaw sets that can be loaded/unloaded while the machine works.

Featured on ST model Intregrex i-450H machines, Mazak’s new parallel-type turrets provide 12 tool positions and a 10,000-rpm rotary tool spindle. The design not only allows for any size tool length to be used, but also eliminates interference when workpieces are held between the machine’s two turning spindles while also reducing

chip accumulation on the machine’s X-axis covers.

The Intregrex i-450H S, which features two turning spindles and a milling spindle headstock for Done In One part production, accommodates a chuck size of 12” and sports a new extended Y-axis stroke of 300 mm and X-axis of 695 mm for maximum part diameters of 670 mm. The main chuck is 3,300 rpm, while the second chuck is 4,000 rpm, and the distance between centers measures 2,500 mm. The milling spindle comes standard as 12,000 rpm (24/22 kW) with a 20,000 rpm (24/22 kW) version offered as an option.

Related Glossary Terms

- centers

centers

Cone-shaped pins that support a workpiece by one or two ends during machining. The centers fit into holes drilled in the workpiece ends. Centers that turn with the workpiece are called “live” centers; those that do not are called “dead” centers.

- chuck

chuck

Workholding device that affixes to a mill, lathe or drill-press spindle. It holds a tool or workpiece by one end, allowing it to be rotated. May also be fitted to the machine table to hold a workpiece. Two or more adjustable jaws actually hold the tool or part. May be actuated manually, pneumatically, hydraulically or electrically. See collet.

- computer numerical control ( CNC)

computer numerical control ( CNC)

Microprocessor-based controller dedicated to a machine tool that permits the creation or modification of parts. Programmed numerical control activates the machine’s servos and spindle drives and controls the various machining operations. See DNC, direct numerical control; NC, numerical control.

- computer-aided manufacturing ( CAM)

computer-aided manufacturing ( CAM)

Use of computers to control machining and manufacturing processes.

- flat ( screw flat)

flat ( screw flat)

Flat surface machined into the shank of a cutting tool for enhanced holding of the tool.

- gang cutting ( milling)

gang cutting ( milling)

Machining with several cutters mounted on a single arbor, generally for simultaneous cutting.

- milling

milling

Machining operation in which metal or other material is removed by applying power to a rotating cutter. In vertical milling, the cutting tool is mounted vertically on the spindle. In horizontal milling, the cutting tool is mounted horizontally, either directly on the spindle or on an arbor. Horizontal milling is further broken down into conventional milling, where the cutter rotates opposite the direction of feed, or “up” into the workpiece; and climb milling, where the cutter rotates in the direction of feed, or “down” into the workpiece. Milling operations include plane or surface milling, endmilling, facemilling, angle milling, form milling and profiling.

- turning

turning

Workpiece is held in a chuck, mounted on a face plate or secured between centers and rotated while a cutting tool, normally a single-point tool, is fed into it along its periphery or across its end or face. Takes the form of straight turning (cutting along the periphery of the workpiece); taper turning (creating a taper); step turning (turning different-size diameters on the same work); chamfering (beveling an edge or shoulder); facing (cutting on an end); turning threads (usually external but can be internal); roughing (high-volume metal removal); and finishing (final light cuts). Performed on lathes, turning centers, chucking machines, automatic screw machines and similar machines.

PRODUCTS

PRODUCTS