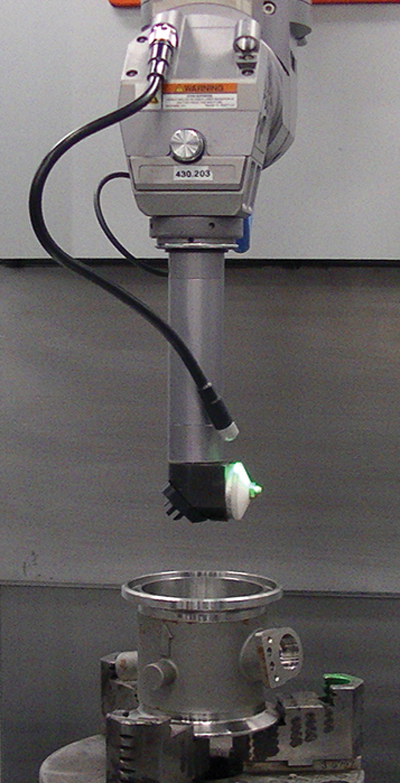

Laserdyne 430 BeamDirector with Right-Angle Nozzle

Laserdyne 430 BeamDirector with Right-Angle Nozzle

The new 430 BeamDirector from Prima Power Laserdyne is available with a newly developed right angle nozzle which is used for close in cutting, welding and drilling.

The new 430 BeamDirector from Prima Power Laserdyne is available with a newly developed right angle nozzle which is used for close in cutting, welding and drilling. Ideal for applications requiring "inside out" processing in very tight areas, the right angle nozzle is another important option for use with the 430's exclusive third generation BeamDirector. It provides C (rotary) axis motion of 900 degrees, and D (tilt) axis motion of 300 degrees at high velocity, accelerations without compromising accuracy.

The small, 1-½ inch wide right angle nozzle will enter and align accurately within any tight space to a depth of (how long is neck) for accurate cutting, welding and drilling. Applications for this special nozzle have included medical devices, surgical instruments, pressure valves, fluid power and fire arm components as well as stamped, drawn and thermoformed parts. A wide range of materials such as stainless steel, titanium and nickel based aerospace alloys can be processed.

The right angle nozzle is easily and quickly installed simply by replacing the standard laser nozzle. This is accomplished without the need for tools. The right angle nozzle offers Laserdyne users expanded flexibility, with many more options and multiple configurations available. What makes the 430 a truly flexible work station is the integration of the BeamDirector's motion and process control capabilities in a space efficient platform coupled with a fiber laser for processing 2D and 3D components.

In addition to the right angle nozzle is ability to utilize standard SP94P control features, which include a full complement of standard Laserdyne hardware and software. These include Automatic Focus Control for capacitive part sensing, patented Optical Focus Control (OFC) for sensing of thermal barrier coated surfaces, ShapeSoft software for programming shaped holes, BreakThrough Detection for drilling clean, consistent holes with the minimum number of pulses, and mapping. The SP94P control includes Laserdyne created macros specific to laser processing allowing for fast time saving programming of complex features and parts. These macros are interchangeable on all Laserdyne product lines with no modifications required.

Additional features on the third generation BeamDirector (BDY) include: optical encoders for improved accuracy and repeatability, higher assist gas air-flow, adjustable mirrors for easy and accurate beam alignment, and cassette mounted lens and cover slides for quick, accurate changeover. Note that the BDY specifications for accuracy and repeatability are referenced at full gas pressure and flow.

The LASERDYNE 430 BeamDirector when equipped with the right angle nozzle option operates at speeds up to 800 inch/min in all axes (0-20 m/min) with bidirectional accuracy of 0.0005 inch (12.7 micrometer). This accuracy is throughout the system's 585 x 408 x 508mm work envelope, making it ideal for demanding process validation and reliability requirements. Accuracy of the new system is certified to ISO 230-1:1996 and 230-2:2006 in accordance with PRIMA POWER LASERDYNE's standard accuracy and repeatability test procedures.