Contact Details

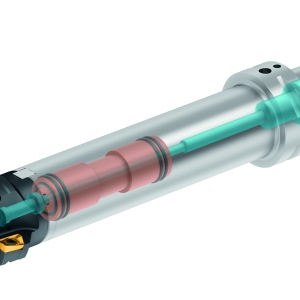

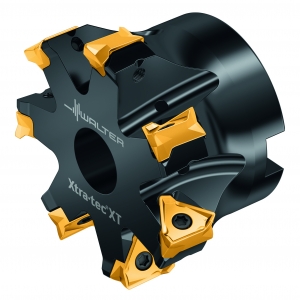

Walter has expanded its cost-effective, flexible M4000 milling cutter system with the addition of the new M4791 routing cutter. Capable of plunging in solid material and producing a true flat bottom, the new routing cutters have an application in both lathes and machining centers.

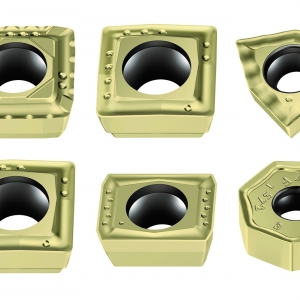

The idea behind the M4000 milling program is that the same indexable insert can be used for all milling cutters in the Walter M4000 family (inserts available in TTS and TTG). The new M4791 tools are offered in diameters of 0.75 in., 1.00 in., 1.25 in. and 1.50 in. with Weldon shanks for secure clamping. A variety of insert are available with insert geometries of A57, D51, D57, F57 and G88 so the exact geometry can be matched to the demands of the machining application.

The M4791, along with the entire M4000 milling cutter family, was designed around efficiency and economy. Efficiency is realized by minimizing cycle time, power consumption and stocking complexity. Economic benefits come from long tool life provided by superior insert grades such as Tiger∙tec Gold and the utilization of a system insert for the entire program, which reduces inventory purchasing requirements.

Related Glossary Terms

- centers

centers

Cone-shaped pins that support a workpiece by one or two ends during machining. The centers fit into holes drilled in the workpiece ends. Centers that turn with the workpiece are called “live” centers; those that do not are called “dead” centers.

- flat ( screw flat)

flat ( screw flat)

Flat surface machined into the shank of a cutting tool for enhanced holding of the tool.

- gang cutting ( milling)

gang cutting ( milling)

Machining with several cutters mounted on a single arbor, generally for simultaneous cutting.

- indexable insert

indexable insert

Replaceable tool that clamps into a tool body, drill, mill or other cutter body designed to accommodate inserts. Most inserts are made of cemented carbide. Often they are coated with a hard material. Other insert materials are ceramic, cermet, polycrystalline cubic boron nitride and polycrystalline diamond. The insert is used until dull, then indexed, or turned, to expose a fresh cutting edge. When the entire insert is dull, it is usually discarded. Some inserts can be resharpened.

- milling

milling

Machining operation in which metal or other material is removed by applying power to a rotating cutter. In vertical milling, the cutting tool is mounted vertically on the spindle. In horizontal milling, the cutting tool is mounted horizontally, either directly on the spindle or on an arbor. Horizontal milling is further broken down into conventional milling, where the cutter rotates opposite the direction of feed, or “up” into the workpiece; and climb milling, where the cutter rotates in the direction of feed, or “down” into the workpiece. Milling operations include plane or surface milling, endmilling, facemilling, angle milling, form milling and profiling.

- milling cutter

milling cutter

Loosely, any milling tool. Horizontal cutters take the form of plain milling cutters, plain spiral-tooth cutters, helical cutters, side-milling cutters, staggered-tooth side-milling cutters, facemilling cutters, angular cutters, double-angle cutters, convex and concave form-milling cutters, straddle-sprocket cutters, spur-gear cutters, corner-rounding cutters and slitting saws. Vertical cutters use shank-mounted cutting tools, including endmills, T-slot cutters, Woodruff keyseat cutters and dovetail cutters; these may also be used on horizontal mills. See milling.

PRODUCTS

PRODUCTS