Contact Details

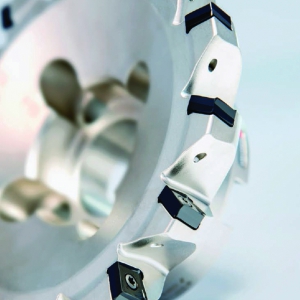

For the utmost in milling productivity, the CERATIZIT MaxiMill 273 Shell Face Milling Cutter provides 16 useable, axially adjustable cutting edges that allow for higher feed rates and guarantee exceptional surface finishes. The MaxiMill 273 is part of CERATIZIT’s line of indexable milling cutters that provide quality and flexibility for all milling operations, whether face milling, shoulder milling or high-feed milling.

The MaxiMill 273 combines all the advantages of positive and negative inserts in one cutter that boosts stability and cost-effectiveness while reducing vibration for superior surface finishes. With an approach angle of 44.6o and a maximum feed rate of 2 mm/rev., the MaxiMill 273’s high insert thicknesses and strong obtuse corner angles improve stability and contribute to excellent system reliability.

Long, consistent tool life enables lights-out, unmanned production thanks to CERATIZIT’s state-of-the-art Dragonskin insert coating technology and efficient wear protection. Plus, the Dragonskin coating gives the inserts added strength for even the most demanding of machining conditions.

The MaxiMill 273 is exceptionally easy to use and utilizes a very simple clamping mechanism that makes incorrect insert clamping virtually impossible, even without additional clamping devices. The cutter allows users to quickly exchange inserts while the tool remains in the machine to significantly shorten setup time.

Related Glossary Terms

- approach angle

approach angle

Angle between the insert’s side-cutting edge and the line perpendicular to the milling cutter’s axis of rotation. Approach angle, which is also known as cutting edge angle, is used with metric units of measurement. See lead angle.

- feed

feed

Rate of change of position of the tool as a whole, relative to the workpiece while cutting.

- gang cutting ( milling)

gang cutting ( milling)

Machining with several cutters mounted on a single arbor, generally for simultaneous cutting.

- milling

milling

Machining operation in which metal or other material is removed by applying power to a rotating cutter. In vertical milling, the cutting tool is mounted vertically on the spindle. In horizontal milling, the cutting tool is mounted horizontally, either directly on the spindle or on an arbor. Horizontal milling is further broken down into conventional milling, where the cutter rotates opposite the direction of feed, or “up” into the workpiece; and climb milling, where the cutter rotates in the direction of feed, or “down” into the workpiece. Milling operations include plane or surface milling, endmilling, facemilling, angle milling, form milling and profiling.

- milling cutter

milling cutter

Loosely, any milling tool. Horizontal cutters take the form of plain milling cutters, plain spiral-tooth cutters, helical cutters, side-milling cutters, staggered-tooth side-milling cutters, facemilling cutters, angular cutters, double-angle cutters, convex and concave form-milling cutters, straddle-sprocket cutters, spur-gear cutters, corner-rounding cutters and slitting saws. Vertical cutters use shank-mounted cutting tools, including endmills, T-slot cutters, Woodruff keyseat cutters and dovetail cutters; these may also be used on horizontal mills. See milling.

PRODUCTS

PRODUCTS