MC Modular Workholding System

MC Modular Workholding System

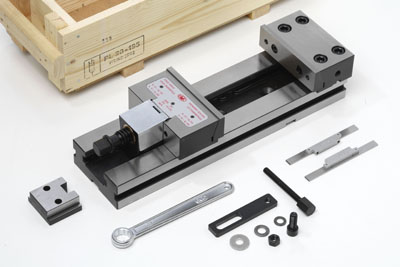

OML's MC Modular Workholding System, which is available from Lexair Inc., uses fixed and movable vise jaws and patented self-locking CLAK parallels to achieve multiple clamping solutions and increased part accuracy with less set up time.

OML's MC Modular Workholding System, which is available from Lexair Inc., uses fixed and movable vise jaws and patented self-locking CLAK parallels to achieve multiple clamping solutions and increased part accuracy with less set up time. Unique features on the MC vise include snap-in, self-locking middle-jaw CLAK parallels that are held in place when the vise is opened in the vertical position, making it ideal for use on tombstones. The CLAK system allows for quick-change of parallels, angular parallels, soft jaws and "V" jaws, making part changeovers and size changes quick and easy. A unique tapered-jaw design pulls the workpiece down against the parallels as the vise is closed, eliminating the need to hammer the part down.

The MC vise is for quick changeovers with a moveable clamping jaw that can be lifted from the base, shuttled to the next position and lowered into place for a different size workpiece. Held in place with a toggle locking mechanism, the moveable jaw unlocks from the base with a flip of the wrist. By relocating the clamp jaw close to the workpiece, the length of the clamp screw can be kept short, minimizing jaw distortion under high force. The clamp screw can also be replaced with a hydraulic cylinder for automated operation.

The MC vise accommodates jaws with rolls, GRIP jaws, aluminum jaws, middle jaws, jaws with grippers UGE, Plus 3D jaws and floating side-ways for raw workpieces. Various jaw adapters, including one for Kurt jaws, allow the use of legacy vise accessories. Adding to their versatility, the vises are easily transported between machine tools. The 6" x 8" (150mm x 200mm) base with a simple clamping system weighs only 55 lbs. (25 kg).

The base length determines the vise's clamping capacity and the jaws can be used with any base configuration, providing a flexible workholding solution with minimum investment. Bases are 6" wide (150mm) and available in 8" (200mm), 10" (250mm), and 12" (300mm) lengths. An 8" (200mm) x 12" (300mm) base is also available, as well as two extended length MC-XL models, with lengths of 21.5" (545mm) and 26" (655mm). All components are constructed from oversize steel profiles and are case hardened and precision ground to ensure exceptional flatness and durability. Wear parts are specially treated for a surface hardness of 50/60 HRC, and all non-ground surfaces are burnished to protect against corrosion.