Contact Details

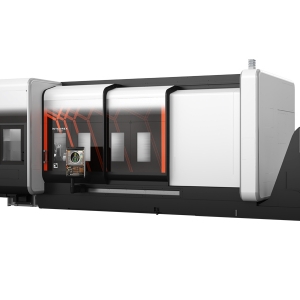

Mazak Corp.'s Mega Turn 900M Vertical Turning Center combines turning and secondary machining operations to efficiently cut large cast iron and steel workpieces, such as those commonly processed in the construction machinery, industrial machinery and jet engine manufacturing sectors.

When used on the machine, Mazak’s Superflow system delivers high-pressure coolant directly to the cutting edge, creating small chips and efficiently evacuating them from the cut. The reduced heat and greater thermal stability provided by the system improves a tool’s cutting action and allows for faster surface speeds and thus increased productivity and minimized tooling costs, especially in challenging applications where poorly controlled, stringy chips can scrap workpieces and cause unexpected tool failure.

In big part applications, the Mega Turn 900M accommodates a maximum workpiece size of 36.2" x 31.5" and utilizes Mazak’s MX hybrid roller guide system to deliver levels of durability and reliability that result in long-term accuracy. The innovative way system reduces vibration, extends tool life, handles higher load capacities and eliminates tramp oil in the coolant by utilizing a greener grease-based lubrication system.

For heavy-duty machining, the machine employs a powerful, rigid 40-hp, 1,250-rpm integrated main drive motor/spindle that generates 2,696 ft.-lbs. of torque. Additionally, the machine carries maximum part loads of 6,614 lbs. (including the chuck).

Mazak designed the Mega Turn 900M with a 12-position drum turret for rapid tool indexing. The turret is rigidly clamped by 16.7 tons of force on a 12.99"-high index coupling, allowing for high performance machining and intermittent cutting. The machine delivers a rotary tool spindle speed of 4,000 rpm and 70.2 ft.-lbs. of torque. It also

removes material at a rate of 58.6 in.3/min., which is 1.4 times higher than comparable vertical turning lathes.

When workpiece applications require two machining operations, Mazak offers the Mega Turn 900M in both left-hand and right-hand spindle orientations, allowing shops to easily pair two machines together in a compact cell that conserves floor space. Mazak can also outfit the machine with an optional toolchanger magazine. This separate magazine can tool change long boring bars in and out of a designated tool pocket and allows for interference-free

cutting when necessary. Offered in magazine sizes of 12, 24 or 36 tool pockets for Capto C6 tooling and 10 tool pockets for Capto C8 tooling, the tool changer provides ample storage room for redundant tooling.

The machine comes standard with Mazak’s Tool Eye, an automatic tool presetting system. By bringing the tool tip into contact with the Tool Eye, offset of tool nose position, tool measurement and data registration are done automatically to ensure accurate and fast part setup. The Tool Eye can also be programmed to monitor tool

wear on a periodic basis.

The Mega Turn 900M is equipped with the Mazatrol SmoothG CNC and its suite of Smooth Technology software solutions. The control’s innovative programming, performance and monitoring functions, as well as the ability to use both EIA/ISO and conversational programming bring optimal speed and accuracy to complex part production.

To further boost its productivity through continuous machining, the Mega Turn 900M can be integrated with an optional two-pallet changer.

Related Glossary Terms

- boring

boring

Enlarging a hole that already has been drilled or cored. Generally, it is an operation of truing the previously drilled hole with a single-point, lathe-type tool. Boring is essentially internal turning, in that usually a single-point cutting tool forms the internal shape. Some tools are available with two cutting edges to balance cutting forces.

- computer numerical control ( CNC)

computer numerical control ( CNC)

Microprocessor-based controller dedicated to a machine tool that permits the creation or modification of parts. Programmed numerical control activates the machine’s servos and spindle drives and controls the various machining operations. See DNC, direct numerical control; NC, numerical control.

- conversational programming

conversational programming

Method for using plain English to produce G-code file without knowing G-code in order to program CNC machines.

- coolant

coolant

Fluid that reduces temperature buildup at the tool/workpiece interface during machining. Normally takes the form of a liquid such as soluble or chemical mixtures (semisynthetic, synthetic) but can be pressurized air or other gas. Because of water’s ability to absorb great quantities of heat, it is widely used as a coolant and vehicle for various cutting compounds, with the water-to-compound ratio varying with the machining task. See cutting fluid; semisynthetic cutting fluid; soluble-oil cutting fluid; synthetic cutting fluid.

- toolchanger

toolchanger

Carriage or drum attached to a machining center that holds tools until needed; when a tool is needed, the toolchanger inserts the tool into the machine spindle. See automatic toolchanger.

- tramp oil

tramp oil

Oil that is present in a metalworking fluid mix that is not from the product concentrate. The usual sources are machine tool lubrication system leaks.

- turning

turning

Workpiece is held in a chuck, mounted on a face plate or secured between centers and rotated while a cutting tool, normally a single-point tool, is fed into it along its periphery or across its end or face. Takes the form of straight turning (cutting along the periphery of the workpiece); taper turning (creating a taper); step turning (turning different-size diameters on the same work); chamfering (beveling an edge or shoulder); facing (cutting on an end); turning threads (usually external but can be internal); roughing (high-volume metal removal); and finishing (final light cuts). Performed on lathes, turning centers, chucking machines, automatic screw machines and similar machines.

PRODUCTS

PRODUCTS