Contact Details

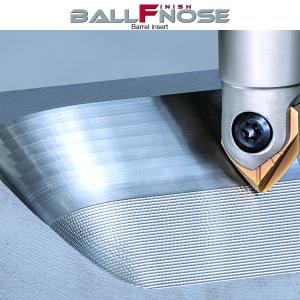

Tungaloy has introduced eight new CBN inserts with HP chipbreaker for its MiniForce-Turn turning insert family of double-sided positive geometry.

The MiniForce-Turn series offers innovative double-sided turning inserts with positive rake cutting edges on both sides. These proven inserts are capable of soft cutting action similar to that of positive inserts with an added advantage of double cutting edges.

New MiniForce-Turn CBN inserts feature HP chipbreaker and use unique WavyJoint brazing technology for the CBN tips, providing enhanced insert reliability during hard turning.

HP chipbreaker demonstrates excellent chip control during hard turning at 0.2 mm (.008″) or smaller depths of cut. The chipbreaker is designed with a strategical distance between the cutting edge and chip redirector. This not only inhibits crater wear development on the rake face for maximum tool life but also helps lighten cutting forces during machining, eliminating chatter marks and part scraps for improved machining stability.

Two CBN insert grades are available for further empowerment of hard turning productivity: general-purpose BXA20 grade covers an extensive application range from continuous to interrupted cuts at low to medium cutting speeds; while BXA10 grade features good wear resistance in continuous cuts of hardened steel parts, demonstrating exceptional insert reliability and long tool life.

Related Glossary Terms

- chatter

chatter

Condition of vibration involving the machine, workpiece and cutting tool. Once this condition arises, it is often self-sustaining until the problem is corrected. Chatter can be identified when lines or grooves appear at regular intervals in the workpiece. These lines or grooves are caused by the teeth of the cutter as they vibrate in and out of the workpiece and their spacing depends on the frequency of vibration.

- chipbreaker

chipbreaker

Groove or other tool geometry that breaks chips into small fragments as they come off the workpiece. Designed to prevent chips from becoming so long that they are difficult to control, catch in turning parts and cause safety problems.

- cubic boron nitride ( CBN)

cubic boron nitride ( CBN)

Crystal manufactured from boron nitride under high pressure and temperature. Used to cut hard-to-machine ferrous and nickel-base materials up to 70 HRC. Second hardest material after diamond. See superabrasive tools.

- hard turning

hard turning

Single-point cutting of a workpiece that has a hardness value higher than 45 HRC.

- rake

rake

Angle of inclination between the face of the cutting tool and the workpiece. If the face of the tool lies in a plane through the axis of the workpiece, the tool is said to have a neutral, or zero, rake. If the inclination of the tool face makes the cutting edge more acute than when the rake angle is zero, the rake is positive. If the inclination of the tool face makes the cutting edge less acute or more blunt than when the rake angle is zero, the rake is negative.

- turning

turning

Workpiece is held in a chuck, mounted on a face plate or secured between centers and rotated while a cutting tool, normally a single-point tool, is fed into it along its periphery or across its end or face. Takes the form of straight turning (cutting along the periphery of the workpiece); taper turning (creating a taper); step turning (turning different-size diameters on the same work); chamfering (beveling an edge or shoulder); facing (cutting on an end); turning threads (usually external but can be internal); roughing (high-volume metal removal); and finishing (final light cuts). Performed on lathes, turning centers, chucking machines, automatic screw machines and similar machines.

- wear resistance

wear resistance

Ability of the tool to withstand stresses that cause it to wear during cutting; an attribute linked to alloy composition, base material, thermal conditions, type of tooling and operation and other variables.

PRODUCTS

PRODUCTS