Modular Fixturing System

Modular Fixturing System

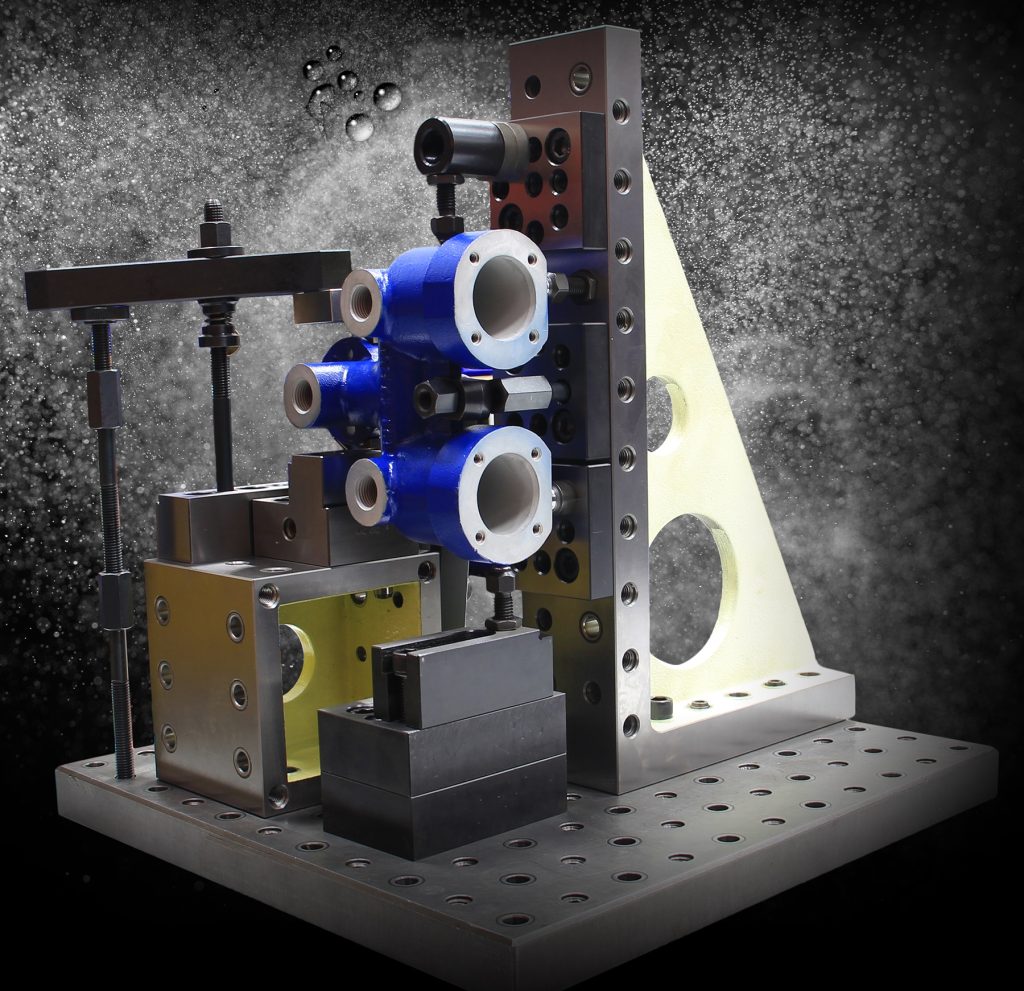

Bluco Corp.'s modular fixturing system is for fixturing low-volume/high-mix work. Using an alternating pattern of dowel and tapped holes, fixture plates are accurate to +/- 0.0004" between centers.

Bluco Corp.'s modular fixturing system is for fixturing low-volume/high-mix work. Using an alternating pattern of dowel and tapped holes, fixture plates are accurate to +/- 0.0004" between centers.

For horizontal applications, baseplates can be integrated with new or existing tombstones. A ball lock feature can be added for off-line fixture setup and quick changeover between jobs. Hundreds of components are available for locating and clamping parts of any style and shape.