Contact Details

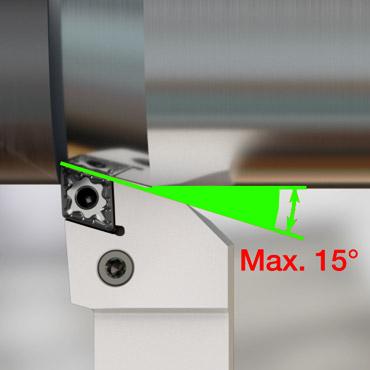

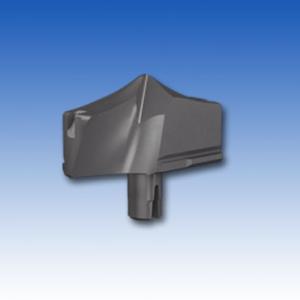

NEOTURN inserts feature a unique head angle of 70° which provides extra clearance compared to conventional CNMG 80° inserts with additional strong points compared to DNMG 55° inserts.

The NEOTURN XNMG inserts have the advantages of both the CNMG and DNMG inserts, and combine the advantages of both which provides the winning edge.

NEOTURN offers the most popular turning chipformers for steels such as F3P and M3P, and F3M and M3M for machining stainless steel in medium and finishing applications.

The NEOTURN XNMG demonstrates excellent chip control and highly stable tool life in a wide range of applications. The NEOTURN system also enables machining complicated workpiece shapes close to the tail stock where space is limited. This can be performed without replacing the holder and decreases setup time substantially.

NEOTURN provides the advantage of using one tool for longitudinal, face and profile turning. The integrated shape of both CNMG and DNMG insert geometries enables the reduction of tool and insert inventory.

Related Glossary Terms

- clearance

clearance

Space provided behind a tool’s land or relief to prevent rubbing and subsequent premature deterioration of the tool. See land; relief.

- turning

turning

Workpiece is held in a chuck, mounted on a face plate or secured between centers and rotated while a cutting tool, normally a single-point tool, is fed into it along its periphery or across its end or face. Takes the form of straight turning (cutting along the periphery of the workpiece); taper turning (creating a taper); step turning (turning different-size diameters on the same work); chamfering (beveling an edge or shoulder); facing (cutting on an end); turning threads (usually external but can be internal); roughing (high-volume metal removal); and finishing (final light cuts). Performed on lathes, turning centers, chucking machines, automatic screw machines and similar machines.

PRODUCTS

PRODUCTS