NX Software with Convergent Modeling

NX Software with Convergent Modeling

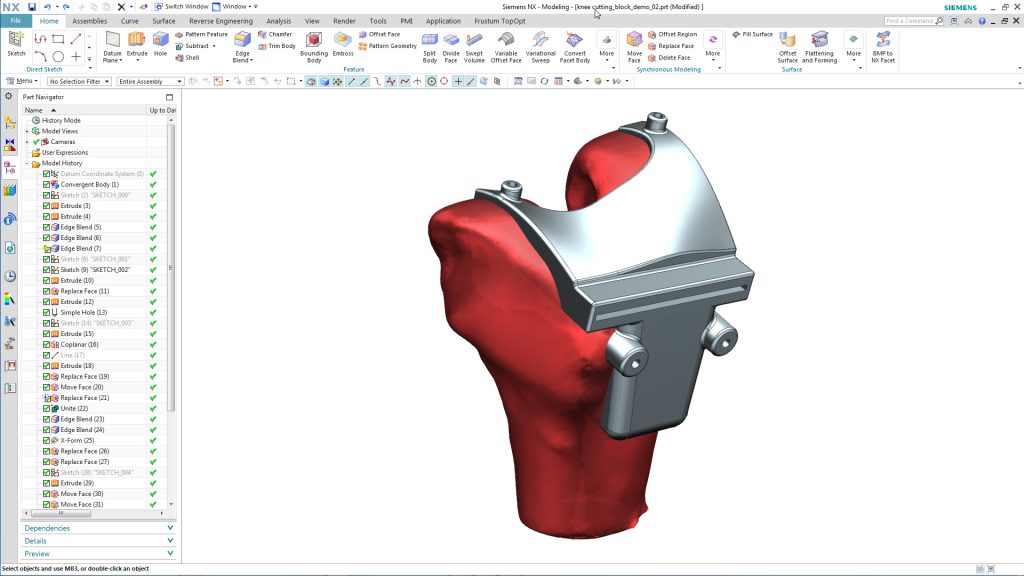

The latest version of Siemens' NX software (NX 11) reportedly delivers a breakthrough in digital product development with Convergent Modeling, a new modeling paradigm that simplifies the ability to work with geometry consisting of a combination of facets, surfaces and solids, without the need for time-consuming data conversion. Convergent Modeling will help engineers optimize part design for 3D printing, speed up the overall design process and make reverse engineering a far more common and efficient practice in product design.

The latest version of Siemens' NX software (NX 11) reportedly delivers a breakthrough in digital product development with Convergent Modeling, a new modeling paradigm that simplifies the ability to work with geometry consisting of a combination of facets, surfaces and solids, without the need for time-consuming data conversion. Convergent Modeling will help engineers optimize part design for 3D printing, speed up the overall design process and make reverse engineering a far more common and efficient practice in product design. In addition, NX 11 includes multiple enhancements throughout the integrated CAD/CAM/CAE solution, such as next generation 3D CAE, powered by the Simcenter 3D software, and improved CAM productivity with tools like robotics machining and hybrid additive manufacturing to help improve productivity.

"Siemens continues to invest in our core products to deliver innovative functionality such as Convergent Modeling, which we believe will be a game changer for digital product design," said Joe Bohman, vice president, Product Engineering Software, Siemens PLM Software. "We anticipate Convergent Modeling will be a critical tool for efficiently working with facet geometry. This new one-of-a-kind technology is expected to provide huge savings in time and cost and help eliminate the error-prone rework phase, common when working with scanned geometry. It also removes the limitations associated with traditional CAD modeling when it comes to optimizing parts for 3D printing.NX11 simplifies the design process and supports the evolution of additive manufacturing to help companies realize a whole new level of creativity in product development."

Product design is partially based on available materials and manufacturing approaches. New techniques like additive manufacturing open the door to create designs with forms and shapes that can provide higher levels of performance. Of course, traditional CAD technologies are built to support traditional manufacturing methods and have limitations when trying to optimize designs for additive manufacturing. Convergent Modeling removes these limitations by giving designers the flexibility to rapidly create new optimal shapes leveraging the materials and techniques made available through additive manufacturing.

Similarly, Convergent Modeling simplifies the process of working with scanned data. Users in various industries, including medical, auto and consumer goods, among others, are increasingly using scanned 3D data as part of the design process. This reverse engineering of existing designs has traditionally been an expensive and tedious process because the scanned data requires a time-consuming manual conversion of the faceted geometry into surface and solid form before it can be used for further modeling. Irregular shapes, in particular, require extensive rework so that they can be used for 3D printing, mold design, analysis or other uses. The reverse engineering process can take days or weeks to complete. Convergent Modeling greatly reduces the need for this rework by bringing the scanned data in as facets that can be worked directly in NX 11, so there is no need to map surfaces, create solids or do any other manual shape creation.

Convergent Modelling allows users to immediately begin using scanned data to create molds based on the shape, include it in an assembly, analyze it or perform any other normal CAD operation. This, combined with the new 3D Print function in NX11 that enables users to 3D print designs directly from NX, significantly simplifies the additive manufacturing process. This new breakthrough scan, edit and print workflow uses the new Microsoft 3D print capabilities and supports the 3MF format to help ensure wide compatibility.

NX 11 also includes several other significant enhancements. Simcenter 3D now powers all simulation capabilities in NX for predicting product performance. Simcenter 3D, which is also available as a standalone application, provides NX users with a seamless experience as they move between design and simulation tasks. It speeds the simulation process by combining best-in-class geometry editing, associative simulation modeling and multi-discipline solutions embedded with industry expertise. Fast and accurate solvers power structural, acoustics, flow, thermal, motion, and composites analysis, as well as optimization and multi-physics simulation. For NX 11, Simcenter 3D introduces new capabilities for modeling and simulation of rotating machinery, a new environment for interior and exterior acoustics, and significant enhancements in damage analysis of composite structures.

Advanced technologies in NX 11 for manufacturing will help manufacturers expand machining flexibility and accuracy, reduce programming time, and improve part quality. New robotic programming capabilities in NX CAM extend the range of machining applications on the shop floor, enabling precise machining of large and complex parts using six-plus axis robots. Robotic machining automates manual operations, including polishing and deburring, improving repeatability to help deliver high quality parts. In addition, the enhanced feature-recognition capability automates NC programming of parts with many holes, to reduce programming time by up to 60 percent. NX CMM Inspection Programming's new high-speed cycle takes measurements by moving only the head, rather than the CMM linear axes. The new head-touches method improves accuracy and speeds up inspection cycles by up to three times.