Contact Details

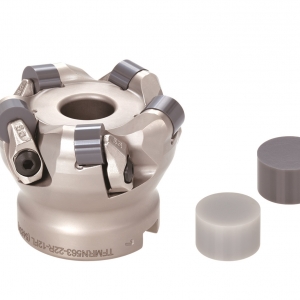

Tungaloy’s PCD turning inserts now feature three-dimensional NS chipbreaker that provides unparalleled chip control in non-ferrous applications for improved productivity.

Long continuous chips generated during the machining of aluminum or copper alloy parts with a conventional PCD insert that has no integrated chipbreaking geometry often cause scratching of the machined surface, exacerbating productivity and resulted surface quality.

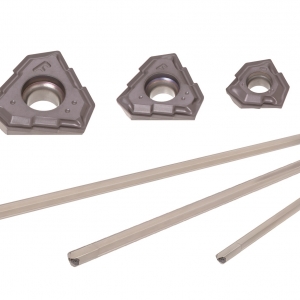

New NS chipbreaker features a three-dimensional chipbreaker that is directly engraved on the PCD tip using the latest technology. This allows the generation of short chips during the machining of gummy metals such as aluminum and copper alloys, significantly reducing machine downtime due to chip associated troubles.

Designed to cater to a wide cutting depth range from extremely light up to 2.0 mm (.079″) DOC, the NS chipbreaker allows a single PCD insert to handle operations from roughing to finishing, enabling users to benefit from the integration of machining processes and reduced insert inventory with improved productivity.

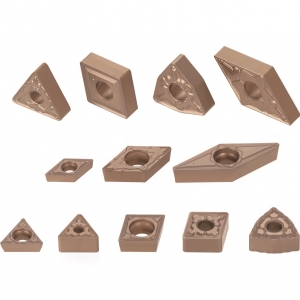

Total of ten new PCD inserts with NS chipbreaker are introduced in DX110 grade that provides the insert with secure edge line for high quality mirror-like surface finish.

Related Glossary Terms

- alloys

alloys

Substances having metallic properties and being composed of two or more chemical elements of which at least one is a metal.

- chipbreaker

chipbreaker

Groove or other tool geometry that breaks chips into small fragments as they come off the workpiece. Designed to prevent chips from becoming so long that they are difficult to control, catch in turning parts and cause safety problems.

- copper alloys

copper alloys

Copper containing specified quantities of alloying elements added to obtain the necessary mechanical and physical properties. The most common copper alloys are divided into six groups, and each group contains one of the following major alloying elements: brasses—major alloying element is zinc; phosphor bronzes—major alloying element is tin; aluminum bronzes—major alloying element is aluminum; silicon bronzes—major alloying element is silicon; copper-nickels and nickel-silvers—major alloying element is nickel; and dilute-copper or high-copper alloys, which contain small amounts of various elements such as beryllium, cadmium, chromium or iron.

- polycrystalline diamond ( PCD)

polycrystalline diamond ( PCD)

Cutting tool material consisting of natural or synthetic diamond crystals bonded together under high pressure at elevated temperatures. PCD is available as a tip brazed to a carbide insert carrier. Used for machining nonferrous alloys and nonmetallic materials at high cutting speeds.

- turning

turning

Workpiece is held in a chuck, mounted on a face plate or secured between centers and rotated while a cutting tool, normally a single-point tool, is fed into it along its periphery or across its end or face. Takes the form of straight turning (cutting along the periphery of the workpiece); taper turning (creating a taper); step turning (turning different-size diameters on the same work); chamfering (beveling an edge or shoulder); facing (cutting on an end); turning threads (usually external but can be internal); roughing (high-volume metal removal); and finishing (final light cuts). Performed on lathes, turning centers, chucking machines, automatic screw machines and similar machines.

PRODUCTS

PRODUCTS