PHT Series Welded Tombstone Columns

PHT Series Welded Tombstone Columns

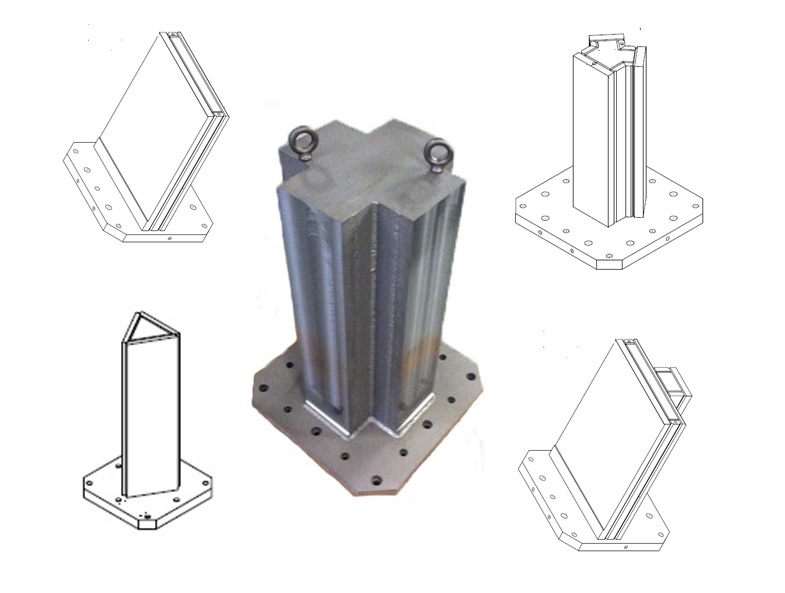

Powerhold Inc. announces the release of its new PHT series welded tombstone columns for horizontal machining centers. The PHT Series are steel plate weldments, available in 400, 500 and 630 mm base sizes.

Powerhold Inc. announces the release of its new PHT series welded tombstone columns for horizontal machining centers. The PHT Series are steel plate weldments, available in 400, 500 and 630 mm base sizes. Twelve different standard configurations are offered, including triangle, 3-side-Y, cross, hexagon and octagon.

Unlike the traditional cast aluminum or steel columns offered by many suppliers, the PHT series can easily be made to suit your particular configuration needs. Overall height, faceplate width, special clearance, and other specific needs can easily be designed into the weldments to meet a specific part requirement.

Powerhold has produced hundreds of welded columns over the past 5 years. Approval prints are provided in 1 week for all orders, to ensure customers are getting exactly what they expected in their tombstone layout. Columns are manufactured with blank faces for customers to finish as needed on their mill.