ProductionACE Production Management System

ProductionACE Production Management System

The ProductionACE Production Management System from Production Process has three new tools that boost manufacturing productivity through the use of smartphones and tablet PCs.

The ProductionACE Production Management System from Production Process has three new tools that boost manufacturing productivity through the use of smartphones and tablet PCs:

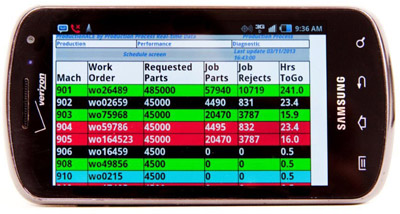

1. User-customizable displays inform Production Managers of machine status and overall productivity/OEE in real time.

2. Automated e-mail alerts notify Maintenance personnel of potential machine problems before productivity suffers.

3. Job completion dates, based on current shop floor conditions, are accessible in real time to Production Schedulers and Sales departments.

The ProductionACE system consists of Machine Data Transducers (MDT) able to communicate with all types of production equipment. They connect directly to machine via discrete, on/off electrical signals, thus completely sidestepping the difficult task of integrating a variety of machines with differing communication technologies/protocols. Windows software collects reports and displays production and productivity data, including machine cycle time and production rate, parts and reject counts, run time and down time, OEE, utilization, directly to a smartphone, tablet or networked PC.

Three models of MDTs and two levels of software enable a manufacturer to match tailor system functionality to their particular operations. Complete system price (software and MDT) for typical 25-machine installation starts at under $700 per machine.

"You cannot improve performance unless you measure it," says Karl Ritzinger, president of Production Process. "Our aim is to provide a practical, economical way for manufacturers to actively monitor their shop floor to ensure their operations are running efficiently."