Contact Details

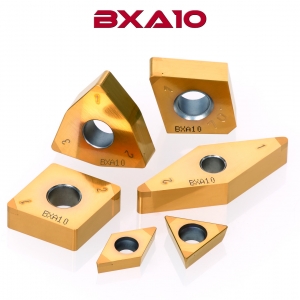

Tungaloy adds PVD-coated grade AH8015 in several geometry types to its MiniForce-Turn series for machining heat-resistant superalloys, steel and stainless steel.

MiniForce-Turn is a successful line of turning tools that feature an innovative double-sided positive insert and unique seat interface for secure location, which is as free cutting as standard single-sided positive inserts with maximum stability and tool economy.

Intended primarily for machining heat-resistant superalloys, the new PVD-coated grade AH8015 also exhibits excellent performance in steel and stainless steel machining with a balanced resistance to wear and chipping.

AH8015 is offered in the -TS, -SS, and -TSW style chipbreakers on six-cornered WXGU0403 inserts and four-cornered DXGU0703 inserts to provide longer and more predictable tool life over existing grades in a wide range of applications and materials.

Related Glossary Terms

- superalloys

superalloys

Tough, difficult-to-machine alloys; includes Hastelloy, Inconel and Monel. Many are nickel-base metals.

- turning

turning

Workpiece is held in a chuck, mounted on a face plate or secured between centers and rotated while a cutting tool, normally a single-point tool, is fed into it along its periphery or across its end or face. Takes the form of straight turning (cutting along the periphery of the workpiece); taper turning (creating a taper); step turning (turning different-size diameters on the same work); chamfering (beveling an edge or shoulder); facing (cutting on an end); turning threads (usually external but can be internal); roughing (high-volume metal removal); and finishing (final light cuts). Performed on lathes, turning centers, chucking machines, automatic screw machines and similar machines.

PRODUCTS

PRODUCTS