Contact Details

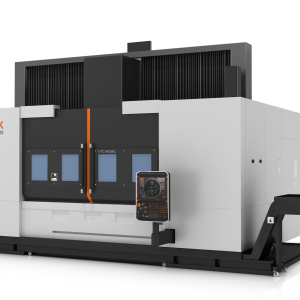

For those shops looking to boost productivity as well as profitability, Mazak’s QUICK TURN-250MSY turning center sports several new productivity-enhancing features. These include a new direct-drive turret design, higher torque main spindle, a faster more powerful milling spindle and the MAZATROL SmoothG CNC.

The QUICK TURN-250MSY – with multitasking functionality – has two turning spindles, a rotary tool milling spindle and Y-axis capabilities for single setup part processing operations. The machine’s new 12-position, direct-drive turret eliminates the use of belts for improved part surface finishes and reduced maintenance. It accepts both VDI and bolt-on tooling.

The turret’s standard direct-drive rotary tool spindle is now 10 hp, 6,000 rpm. The faster rotary spindle provides 52 ft.-lbs. of torque, essentially double of what was possible before with the previous version. And with an optional tooling package, 10,000 rpm is available.

The machine’s headstock features a 10" main chuck mounted on a 35-hp, 4,000-rpm integrated spindle motor for heavy-duty metal removal. To effectively tackle today’s tough part materials, Mazak bumped up the torque output of the spindle by almost 30 ft.-lbs. The main turning spindle also serves as a C-axis that is programmable in 0.0001-degree increments to accurately position parts for square facing and slotting cuts and precisely drilled holes. The C-axis spindle is a full-function CNC controlled axis for milling. A second turning 15-hp, 6,000-rpm spindle with a 6" chuck allows the QUICK TURN-250MSY to machine small diameter workpieces with speed and accuracy.

The QUICK TURN-250 machine models without second turning spindles feature Mazak’s new NC servo-drilling tailstocks as standard. The fully programmable tailstock drives the W-axis on its own AC servomotor and ball screw. Through the part program, the tailstock will retract to a known position and its center makes contact with the part with consistent holding pressure. Thrust settings are completely adjustable – high thrust or low thrust – without having to retouch the part.

Mazak’s MAZATROL SmoothC and SmoothG CNCs offer EIA/ISO programming as well as conversational programming that makes it easy to generate programs for complex drilling, milling or tapping operations. The controls also feature advanced hardware and software functions that help ensure high productivity and performance accuracy in challenging part production operations.

As a higher level control, the MAZATROL SmoothG incorporates a wide variety of advanced programming functions for ease of use and to ensure high-speed, high-accuracy machining performance. These functions include High Gain Feed Forward Control, Fast Rotary Axis Speeds, Variable Acceleration Control and Intelligent Pocket Milling.

A variety of automation strategies can be integrated with the QUICK TURN-250MSY, from an automatic bar feeder to gantry robots, for improved spindle utilization and a significant boost in productivity.

Related Glossary Terms

- chuck

chuck

Workholding device that affixes to a mill, lathe or drill-press spindle. It holds a tool or workpiece by one end, allowing it to be rotated. May also be fitted to the machine table to hold a workpiece. Two or more adjustable jaws actually hold the tool or part. May be actuated manually, pneumatically, hydraulically or electrically. See collet.

- computer numerical control ( CNC)

computer numerical control ( CNC)

Microprocessor-based controller dedicated to a machine tool that permits the creation or modification of parts. Programmed numerical control activates the machine’s servos and spindle drives and controls the various machining operations. See DNC, direct numerical control; NC, numerical control.

- conversational programming

conversational programming

Method for using plain English to produce G-code file without knowing G-code in order to program CNC machines.

- feed

feed

Rate of change of position of the tool as a whole, relative to the workpiece while cutting.

- gang cutting ( milling)

gang cutting ( milling)

Machining with several cutters mounted on a single arbor, generally for simultaneous cutting.

- milling

milling

Machining operation in which metal or other material is removed by applying power to a rotating cutter. In vertical milling, the cutting tool is mounted vertically on the spindle. In horizontal milling, the cutting tool is mounted horizontally, either directly on the spindle or on an arbor. Horizontal milling is further broken down into conventional milling, where the cutter rotates opposite the direction of feed, or “up” into the workpiece; and climb milling, where the cutter rotates in the direction of feed, or “down” into the workpiece. Milling operations include plane or surface milling, endmilling, facemilling, angle milling, form milling and profiling.

- numerical control ( NC)

numerical control ( NC)

Any controlled equipment that allows an operator to program its movement by entering a series of coded numbers and symbols. See CNC, computer numerical control; DNC, direct numerical control.

- slotting

slotting

Machining, normally milling, that creates slots, grooves and similar recesses in workpieces, including T-slots and dovetails.

- tapping

tapping

Machining operation in which a tap, with teeth on its periphery, cuts internal threads in a predrilled hole having a smaller diameter than the tap diameter. Threads are formed by a combined rotary and axial-relative motion between tap and workpiece. See tap.

- turning

turning

Workpiece is held in a chuck, mounted on a face plate or secured between centers and rotated while a cutting tool, normally a single-point tool, is fed into it along its periphery or across its end or face. Takes the form of straight turning (cutting along the periphery of the workpiece); taper turning (creating a taper); step turning (turning different-size diameters on the same work); chamfering (beveling an edge or shoulder); facing (cutting on an end); turning threads (usually external but can be internal); roughing (high-volume metal removal); and finishing (final light cuts). Performed on lathes, turning centers, chucking machines, automatic screw machines and similar machines.

PRODUCTS

PRODUCTS