R-Drill 200

R-Drill 200

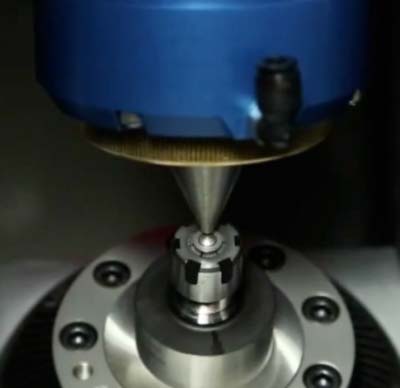

Raydiance Inc., an industrial grade femtosecond laser manufacturer based in Petaluma, Calif., recently introduced the R-Drill 200 — a packaged, factory-ready microhole drilling solution for precision manufacturers.

Raydiance Inc., an industrial grade femtosecond laser manufacturer based in Petaluma, Calif., recently introduced the R-Drill 200 — a packaged, factory-ready microhole drilling solution for precision manufacturers.

The R-Drill 200 is said to create flawless microholes in less than a second, according to a company news release. The latest R-Drill bundles the Raydiance R-200 femtosecond laser, multi-axis scanning and software that enables the system to be configured to drill to exact geometries in a single step.

According to Raydiance, the company's femtosecond laser machining systems have been replacing legacy electronic discharge machining and slower laser machining products in automotive, medical device and consumer electronics markets. With traditional precision drilling systems such as mechanical punching, EDMing and legacy laser machining, parts face post-processing steps such as abrasive washing, deburring and honing. These steps add cost and also introduce variation from part to part.

Femtosecond lasers machine material without generating heat, which means material is removed to specification and no costly post processing steps are needed to compensate for heat related side effects, according to the Raydiance news release.

"Manufacturers have been waiting for industrial grade femtosecond laser solutions for decades," said Raydiance Vice President of Sales Philippe Brak. "Raydiance solutions cut production costs in half, and accelerate product design and development."

The Raydiance R-Drill 200 joins the R-Drill 100 in the company's product line, delivering unmatched precision solutions that dramatically reduce the price per part in medical, industrial and consumer markets.