Contact Details

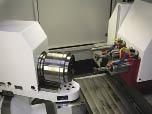

United Grinding Technologies Inc. offers eight Studer CT ID grinding machines for small- to medium-size internal cylindrical grinding applications, such as die plates, spring collets, toolholding fixtures, hydraulic components and thread ring gages. The spindle arrangement enables optimal dimensioning of the machine, ranging from the machining of individual parts to large-scale production, according to the company. The machines support integrated and autonomous loading systems.

Related Glossary Terms

- cylindrical grinding

cylindrical grinding

Grinding operation in which the workpiece is rotated around a fixed axis while the grinding wheel is fed into the outside surface in controlled relation to the axis of rotation. The workpiece is usually cylindrical, but it may be tapered or curvilinear in profile. See centerless grinding; grinding.

- grinding

grinding

Machining operation in which material is removed from the workpiece by a powered abrasive wheel, stone, belt, paste, sheet, compound, slurry, etc. Takes various forms: surface grinding (creates flat and/or squared surfaces); cylindrical grinding (for external cylindrical and tapered shapes, fillets, undercuts, etc.); centerless grinding; chamfering; thread and form grinding; tool and cutter grinding; offhand grinding; lapping and polishing (grinding with extremely fine grits to create ultrasmooth surfaces); honing; and disc grinding.

- inner diameter ( ID)

inner diameter ( ID)

Dimension that defines the inside diameter of a cavity or hole. See OD, outer diameter.

Additional Products from United Grinding North America Inc.

Pagination

- First page

- Previous page

- 1

- 2

- 3

- 4

- 5

PRODUCTS

PRODUCTS