Summit 10.10.10

Summit 10.10.10

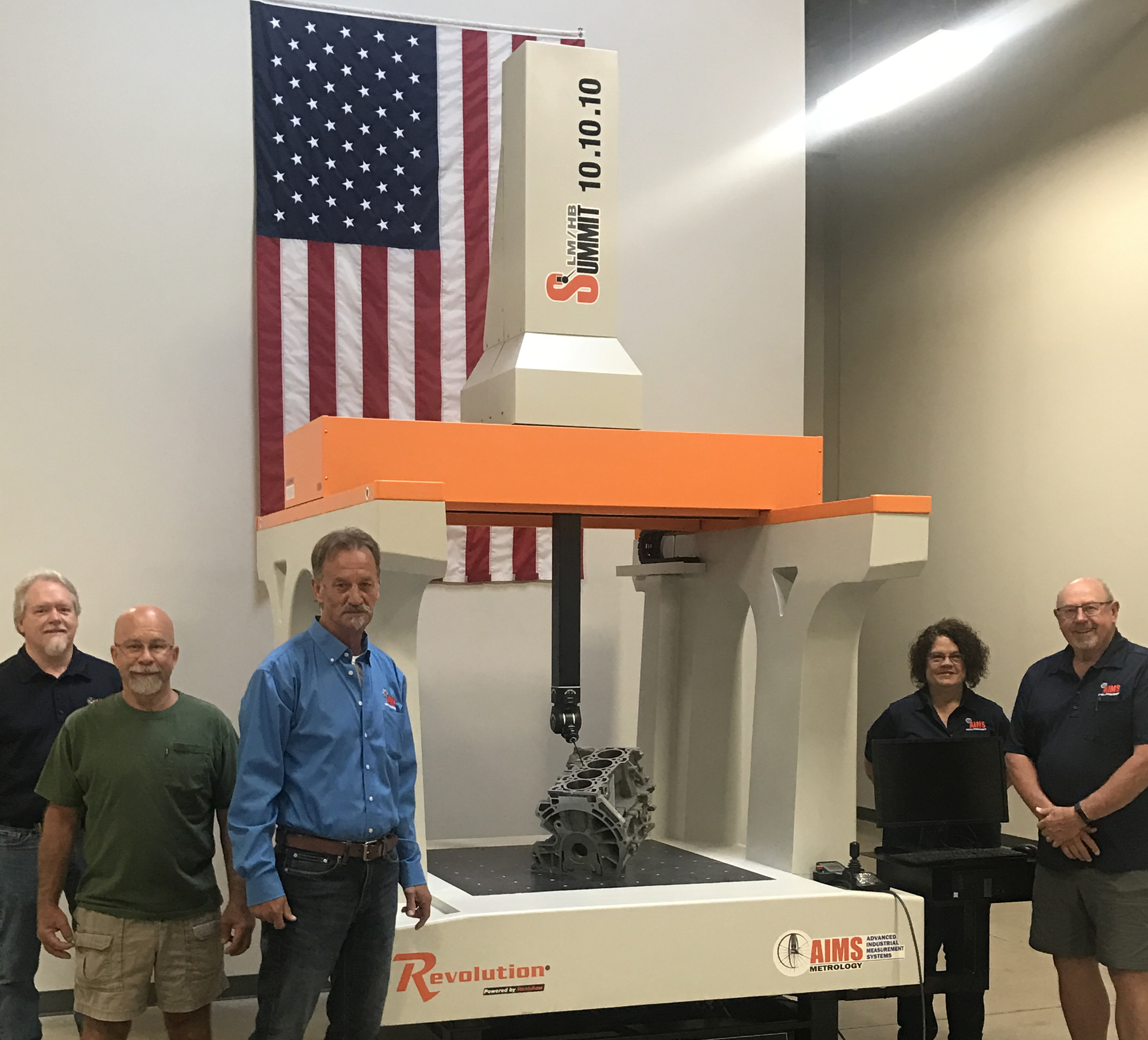

AIMS Metrology, a manufacturer of coordinate measuring machines (CMM) based in Dayton, Ohio, in July introduced its new Summit 10.10.10, a CMM engineered with a 5-axis REVO-2 dynamic scanning probe and 1 meter cubed capacity.

AIMS Metrology, a manufacturer of coordinate measuring machines (CMM) based in Dayton, Ohio, in July introduced its new Summit 10.10.10, a CMM engineered with a 5-axis REVO-2 dynamic scanning probe and 1 meter cubed capacity. The Summit is said to offer a diverse range of industries—including automotive, aerospace and medical—the capacity to handle high volume, large parts inspection. The new CMM can be automated with a robot load/unload system or pass through process with a conveyor.

A stationary model, the Summit is said to be capable of handling a workpiece weight of 2,200 kg while preserving valuable floor space.

"The Summit is a game changer for manufacturers," said AIMS Vice President Mark Gearding. "Its development was prompted by customer requests for large inspection capacity enhanced with REVO-2's latest sensors such as RVP vision and SFP2 surface measurement."

The REVO-2 provides measuring speeds up to 500 mm/second and data collection rates of up to 4,000 points per second for increased part throughput.

AIMS designs and produces coordinate measuring machines integrated with 5-axis measurement technology for accurate, flexible three-dimensional inspection of in-process and post process parts. The company's line of Revolution Series LM and HB CMMs are built in the United States and engineered for the shop floor, the lab and automated applications in smart factory settings.