Contact Details

Walter has launched the TC130 Supreme tapping tool with a new patent-pending geometry for improved surface quality even when threading large batch sizes. Straight grooves produce short, controllable chips, resulting in high process reliability when threading with the TC130 tap. In turn, the special geometry means that the fine surface finish of the threads is maintained longer, so the tap does not need to be replaced prematurely because of decreasing thread quality.

To achieve this capability, the last thread in the chamfer section of the tap is designed to “finish” the thread. This results in an excellent thread surface.

The tap with axial internal coolant has a tough HSS-E substrate to prevent fractures and total breakage. The innovative WY80EH HiPIMS coating improves wear resistance and thread quality, and the tool features an additional WY80AA titanium nitride (TiN) coating to provide the best thread quality. A chamfered guide section prevents fractures at the end of the profile.

With the ability to cut blind-hole threads up to 3.5 × DN, the TC130 Supreme tap is targeted for applications in general mechanical engineering and the energy industry, such as for threading wind turbines. The tap is suitable for threading steel and cast iron (ISO P and K workpiece groups). Also, the tool is ideal for interference contours and series production.

The TC130 Supreme tap has a tolerance of 6HX and is available in a variety of dimensions: UNC ¼ to UNC 1.0, M4 to M42 (metric), and MF10×1 to MF33×2. (metric fine)

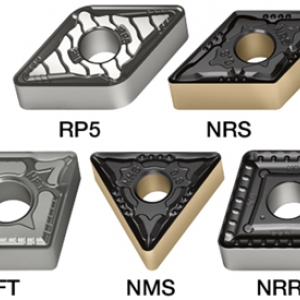

The Walter lineup of products consists of three categories of tools. Supreme tools (such as the TC130) indicate the highest level of technology and performance available. Advance tools indicate products efficiently balanced between price and performance and Perform tools are products that provide an economical solution with focused importance on price.

Related Glossary Terms

- blind-hole

blind-hole

Hole or cavity cut in a solid shape that does not connect with other holes or exit through the workpiece.

- coolant

coolant

Fluid that reduces temperature buildup at the tool/workpiece interface during machining. Normally takes the form of a liquid such as soluble or chemical mixtures (semisynthetic, synthetic) but can be pressurized air or other gas. Because of water’s ability to absorb great quantities of heat, it is widely used as a coolant and vehicle for various cutting compounds, with the water-to-compound ratio varying with the machining task. See cutting fluid; semisynthetic cutting fluid; soluble-oil cutting fluid; synthetic cutting fluid.

- tap

tap

Cylindrical tool that cuts internal threads and has flutes to remove chips and carry tapping fluid to the point of cut. Normally used on a drill press or tapping machine but also may be operated manually. See tapping.

- tapping

tapping

Machining operation in which a tap, with teeth on its periphery, cuts internal threads in a predrilled hole having a smaller diameter than the tap diameter. Threads are formed by a combined rotary and axial-relative motion between tap and workpiece. See tap.

- threading

threading

Process of both external (e.g., thread milling) and internal (e.g., tapping, thread milling) cutting, turning and rolling of threads into particular material. Standardized specifications are available to determine the desired results of the threading process. Numerous thread-series designations are written for specific applications. Threading often is performed on a lathe. Specifications such as thread height are critical in determining the strength of the threads. The material used is taken into consideration in determining the expected results of any particular application for that threaded piece. In external threading, a calculated depth is required as well as a particular angle to the cut. To perform internal threading, the exact diameter to bore the hole is critical before threading. The threads are distinguished from one another by the amount of tolerance and/or allowance that is specified. See turning.

- titanium nitride ( TiN)

titanium nitride ( TiN)

Added to titanium-carbide tooling to permit machining of hard metals at high speeds. Also used as a tool coating. See coated tools.

- tolerance

tolerance

Minimum and maximum amount a workpiece dimension is allowed to vary from a set standard and still be acceptable.

- wear resistance

wear resistance

Ability of the tool to withstand stresses that cause it to wear during cutting; an attribute linked to alloy composition, base material, thermal conditions, type of tooling and operation and other variables.

PRODUCTS

PRODUCTS