Contact Details

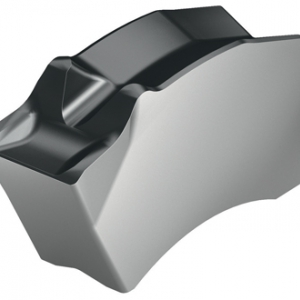

Walter has introduced its latest orbital thread mills, the Thread Mill Orbital Unified National Fine (UNF) 2xD and 3xD models. Their large shank diameters promote vibration free machining, even with a long clamping length, and their wear resistant, tough micrograin carbide construction with TiCN coating renders them suitable for use with ISO material types P, M, K, N, S and O.

Both the UNF 2xD and 3xD exhibit superior behavior over the lifetime of the tool, and their short overhang renders them particularly suitable for the machining of challenging materials such as ISO S alloys, materials of higher tensile strength and materials with spring back effect.

This combination of design features, along with the inherent advantages of thread milling itself, enable the Walter Orbital Thread Mill UNF 2xD and 3xD to deliver higher process reliability, particularly crucial when dealing with today's higher value workpieces, along with more true to gauge threads before manual corrections are necessary. In addition, their ability to run with a higher chip load permits a reduced number of passes. This shortens cycle time and allows longer machine time without manual adjustments, according to the company.

Related Glossary Terms

- alloys

alloys

Substances having metallic properties and being composed of two or more chemical elements of which at least one is a metal.

- gang cutting ( milling)

gang cutting ( milling)

Machining with several cutters mounted on a single arbor, generally for simultaneous cutting.

- milling

milling

Machining operation in which metal or other material is removed by applying power to a rotating cutter. In vertical milling, the cutting tool is mounted vertically on the spindle. In horizontal milling, the cutting tool is mounted horizontally, either directly on the spindle or on an arbor. Horizontal milling is further broken down into conventional milling, where the cutter rotates opposite the direction of feed, or “up” into the workpiece; and climb milling, where the cutter rotates in the direction of feed, or “down” into the workpiece. Milling operations include plane or surface milling, endmilling, facemilling, angle milling, form milling and profiling.

- milling machine ( mill)

milling machine ( mill)

Runs endmills and arbor-mounted milling cutters. Features include a head with a spindle that drives the cutters; a column, knee and table that provide motion in the three Cartesian axes; and a base that supports the components and houses the cutting-fluid pump and reservoir. The work is mounted on the table and fed into the rotating cutter or endmill to accomplish the milling steps; vertical milling machines also feed endmills into the work by means of a spindle-mounted quill. Models range from small manual machines to big bed-type and duplex mills. All take one of three basic forms: vertical, horizontal or convertible horizontal/vertical. Vertical machines may be knee-type (the table is mounted on a knee that can be elevated) or bed-type (the table is securely supported and only moves horizontally). In general, horizontal machines are bigger and more powerful, while vertical machines are lighter but more versatile and easier to set up and operate.

- shank

shank

Main body of a tool; the portion of a drill or similar end-held tool that fits into a collet, chuck or similar mounting device.

- tensile strength

tensile strength

In tensile testing, the ratio of maximum load to original cross-sectional area. Also called ultimate strength. Compare with yield strength.

- titanium carbonitride ( TiCN)

titanium carbonitride ( TiCN)

Often used as a tool coating. See coated tools.

PRODUCTS

PRODUCTS