Contact Details

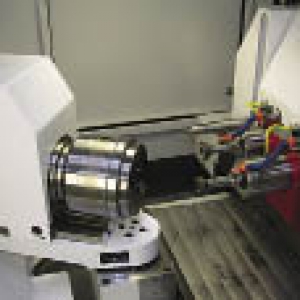

WALTER says it offers a completely new type of loading system for new machines of the types HELITRONIC MINI POWER, HELITRONIC DIAMOND EVOLUTION and HELITRONIC ESSENTIAL. The new space-saving and cost-effective automation solution "Top loader" is integrated directly into the machine, therefore requiring no additional floor space and no restriction of the working envelope of the machine.

The "Top loader" is equipped with a swivelling arm with a single gripper and uses the standard WALTER robot pallets—one for the blanks and one for finished tools. Depending on the tool diameter, these pallets can be loaded with up to 500 tools. A tool change takes only 27 seconds. The setup of the tool pallets is completed automatically through an electrical teaching routine (patent pending) for ease of use and simplicity of changeover.

Additional Products from United Grinding North America Inc.

Pagination

- First page

- Previous page

- 1

- 2

- 3

- 4

- 5

PRODUCTS

PRODUCTS