Contact Details

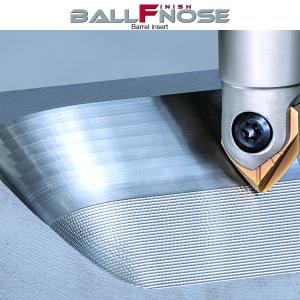

Tungaloy has expanded its TungForce-Feed line of small-diameter high feed milling cutters by adding new cutter diameters.

TungForce-Feed features a large rake angle and positive inclination angle on the cutting edge that provide excellent chip control while reducing spindle loads and energy consumption. This allows a higher feed rate or greater depth of cut to be applied for improved efficiency and, by working in synergy with the cutter’s high insert density design, produces 130%-150% gain in metal removal rates.

A strong insert corner is built with an added thickness that withstands high cutting force and prevents the cutting edge from fracturing. The toolholder has robust M2 screws that makes handling easier and reduces screw neck shearing that can be a common occurrence during high cutting force applications.

The proven success of the TungForce-Feed line of indexable high feed milling cutters has promoted an expansion to include cutters in 20 mm and 25 mm metric diameters and 0.75" and 1.00" imperial. These new cutter diameters join the existing range from 8 mm to 16 mm. This addition enhances the cutters’ application range in exotic materials for cutting depths of 0.5 mm or less.

TungForce-Feed boasts a higher insert density when compared with competitors’ cutters of the same size, allowing higher table feeds to be applied for exceptional manufacturing economy. The cutter is particularly effective and beneficial for manufacturers of exotic material components, typical in the aerospace and heavy industries, who are struggling with machining inefficiency with unpredictable tool life. It allows increased feed per tooth with high insert density for improved metal removal rates and long, predictable tool life

At a Glance

- Enhanced tool lineup for expanded coverage

- High insert density for added productivity

- Robust cutter design ensures process reliability for small inserts

- Total of 16 cutters to be added including 10 metric and 6 imperial cutters

Related Glossary Terms

- cutting force

cutting force

Engagement of a tool’s cutting edge with a workpiece generates a cutting force. Such a cutting force combines tangential, feed and radial forces, which can be measured by a dynamometer. Of the three cutting force components, tangential force is the greatest. Tangential force generates torque and accounts for more than 95 percent of the machining power. See dynamometer.

- depth of cut

depth of cut

Distance between the bottom of the cut and the uncut surface of the workpiece, measured in a direction at right angles to the machined surface of the workpiece.

- feed

feed

Rate of change of position of the tool as a whole, relative to the workpiece while cutting.

- gang cutting ( milling)

gang cutting ( milling)

Machining with several cutters mounted on a single arbor, generally for simultaneous cutting.

- inclination angle

inclination angle

Angle that the cutter edge makes with a plane that is perpendicular to the direction of tool travel. Determines the direction the chip curls.

- milling

milling

Machining operation in which metal or other material is removed by applying power to a rotating cutter. In vertical milling, the cutting tool is mounted vertically on the spindle. In horizontal milling, the cutting tool is mounted horizontally, either directly on the spindle or on an arbor. Horizontal milling is further broken down into conventional milling, where the cutter rotates opposite the direction of feed, or “up” into the workpiece; and climb milling, where the cutter rotates in the direction of feed, or “down” into the workpiece. Milling operations include plane or surface milling, endmilling, facemilling, angle milling, form milling and profiling.

- rake

rake

Angle of inclination between the face of the cutting tool and the workpiece. If the face of the tool lies in a plane through the axis of the workpiece, the tool is said to have a neutral, or zero, rake. If the inclination of the tool face makes the cutting edge more acute than when the rake angle is zero, the rake is positive. If the inclination of the tool face makes the cutting edge less acute or more blunt than when the rake angle is zero, the rake is negative.

- toolholder

toolholder

Secures a cutting tool during a machining operation. Basic types include block, cartridge, chuck, collet, fixed, modular, quick-change and rotating.

PRODUCTS

PRODUCTS