Contact Details

Experience unmatched productivity and reliability in heavy-duty grooving and wide-profile grooving with Tungaloy's TungHeavyGroove grooving inserts and toolholders. Our latest innovation introduces an enhanced insert clamping design, for maximum tool rigidity.

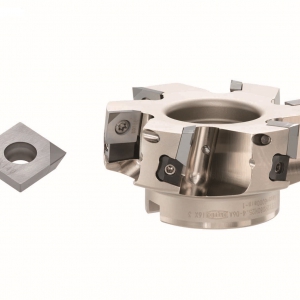

TungHeavyGroove indexable grooving tool line is developed for efficient heavy-duty grooving and wide profile grooving applications, offering inserts in widths of 10, 15, 20, and 25 millimeters.

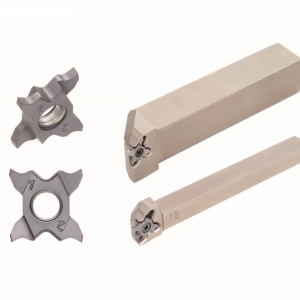

New SHER-CHP toolholders incorporate unique durable features that enhance the tool reliability. Having a thick strong structure, the toolholder supports the insert underneath its cutting edge, contrary to the conventional toolholders, which offer no support directly under the cutting edge. This provides the insert with extra security in sustaining heavy cutting loads during machining. Our toolholders feature a reinforced design that may look unconventional but offers multiple contact faces. This design maximizes contact with the machine turret or tool post, resulting in significantly higher stability and rigidity compared to conventional toolholders. Generally in grooving, and particularly in deep grooving, the chip flow prevents the coolant from reaching the cutting edge.

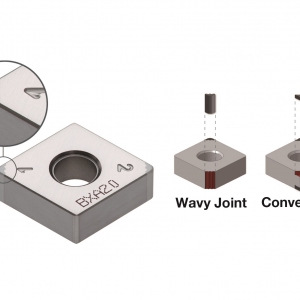

The new TungHeavyGroove toolholders utilize a frontal coolant system, delivering high-pressure cutting fluid from the bottom to the flank face of the cutting edge. This innovative design enhances chip evacuation and extends insert tool life significantly. Furthermore, an extremely rigid dovetail insert clamping method sustains heavy cutting loads during aggressive wide grooving and profile grooving, while providing process security.

Ten new inserts are introduced in total, including two geometries. HGM grooving inserts incorporate a pressed-in chip former and are available in versatile AH8015 grade or T9215 grade optimized for high speed machining of steel. HBL inserts are available as blanks so that users can tailor them into customer-specific groove forms of up to 6.6 millimeter (.260″) depth of cut. HBL is made from versatile TH10 uncoated carbide grade.

16 new square shank toolholders are introduced in both metric and imperial sizes with shank heights and widths of 25x25, 32x32, and 40x40 mm for metric sizes and 1″x1″, 1 ¼″x1 ¼″, and 1 ½″x1 ½″ for imperial sizes.

Related Glossary Terms

- coolant

coolant

Fluid that reduces temperature buildup at the tool/workpiece interface during machining. Normally takes the form of a liquid such as soluble or chemical mixtures (semisynthetic, synthetic) but can be pressurized air or other gas. Because of water’s ability to absorb great quantities of heat, it is widely used as a coolant and vehicle for various cutting compounds, with the water-to-compound ratio varying with the machining task. See cutting fluid; semisynthetic cutting fluid; soluble-oil cutting fluid; synthetic cutting fluid.

- cutting fluid

cutting fluid

Liquid used to improve workpiece machinability, enhance tool life, flush out chips and machining debris, and cool the workpiece and tool. Three basic types are: straight oils; soluble oils, which emulsify in water; and synthetic fluids, which are water-based chemical solutions having no oil. See coolant; semisynthetic cutting fluid; soluble-oil cutting fluid; synthetic cutting fluid.

- depth of cut

depth of cut

Distance between the bottom of the cut and the uncut surface of the workpiece, measured in a direction at right angles to the machined surface of the workpiece.

- grooving

grooving

Machining grooves and shallow channels. Example: grooving ball-bearing raceways. Typically performed by tools that are capable of light cuts at high feed rates. Imparts high-quality finish.

- shank

shank

Main body of a tool; the portion of a drill or similar end-held tool that fits into a collet, chuck or similar mounting device.

- toolholder

toolholder

Secures a cutting tool during a machining operation. Basic types include block, cartridge, chuck, collet, fixed, modular, quick-change and rotating.

PRODUCTS

PRODUCTS