Contact Details

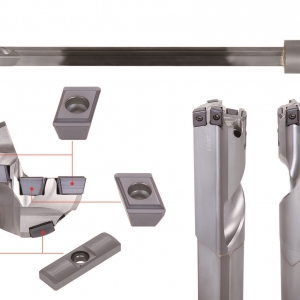

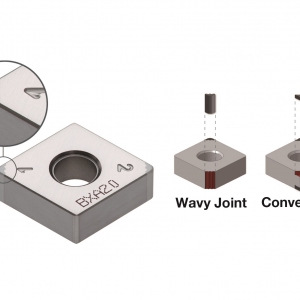

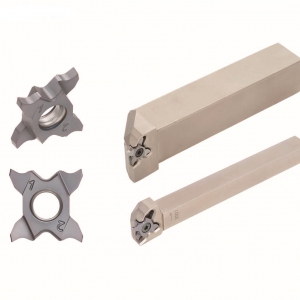

Tungaloy Corp. has expanded the TungTurn-Jet line, the turning tool system with high-pressure coolant capability. Until now, coolant was simply applied by flooding the cutting area, which can cause chips generated during machining to interfere with the coolant flow, preventing it from reaching the exact spot where needed. Tungaloy's TungTurn-Jet’s high-pressure, double-jet coolant system delivers jets of coolant to the optimal position close to the cutting edge and increases productivity by forming short chips in machining difficult-to-cut materials like heat-resistant superalloys.

Tool life is also extended using the second coolant jet from the frontal hole to the cutting point to prevent flank wear on the insert.

Even when using normal coolant pressure and existing equipment, TungTurn-Jet improves tool life for stainless and alloy steels, as well as heat-resistant superalloys in aerospace, automotive and general engineering industries.

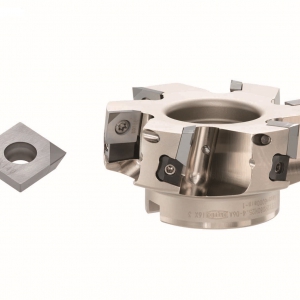

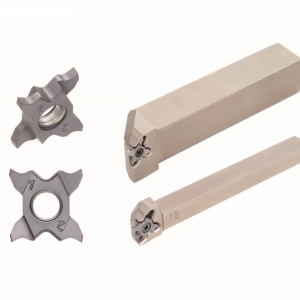

This expansion also adds new lines to the ISO-EcoTurn range to further expand its turning capability in a multitude of industries.

Related Glossary Terms

- alloy steels

alloy steels

Steel containing specified quantities of alloying elements (other than carbon and the commonly accepted amounts of manganese, sulfur and phosphorus) added to cause changes in the metal’s mechanical and/or physical properties. Principal alloying elements are nickel, chromium, molybdenum and silicon. Some grades of alloy steels contain one or more of these elements: vanadium, boron, lead and copper.

- coolant

coolant

Fluid that reduces temperature buildup at the tool/workpiece interface during machining. Normally takes the form of a liquid such as soluble or chemical mixtures (semisynthetic, synthetic) but can be pressurized air or other gas. Because of water’s ability to absorb great quantities of heat, it is widely used as a coolant and vehicle for various cutting compounds, with the water-to-compound ratio varying with the machining task. See cutting fluid; semisynthetic cutting fluid; soluble-oil cutting fluid; synthetic cutting fluid.

- flank wear

flank wear

Reduction in clearance on the tool’s flank caused by contact with the workpiece. Ultimately causes tool failure.

- superalloys

superalloys

Tough, difficult-to-machine alloys; includes Hastelloy, Inconel and Monel. Many are nickel-base metals.

- turning

turning

Workpiece is held in a chuck, mounted on a face plate or secured between centers and rotated while a cutting tool, normally a single-point tool, is fed into it along its periphery or across its end or face. Takes the form of straight turning (cutting along the periphery of the workpiece); taper turning (creating a taper); step turning (turning different-size diameters on the same work); chamfering (beveling an edge or shoulder); facing (cutting on an end); turning threads (usually external but can be internal); roughing (high-volume metal removal); and finishing (final light cuts). Performed on lathes, turning centers, chucking machines, automatic screw machines and similar machines.

PRODUCTS

PRODUCTS