UMA Smart Station for Automating Parts Measurement

UMA Smart Station for Automating Parts Measurement

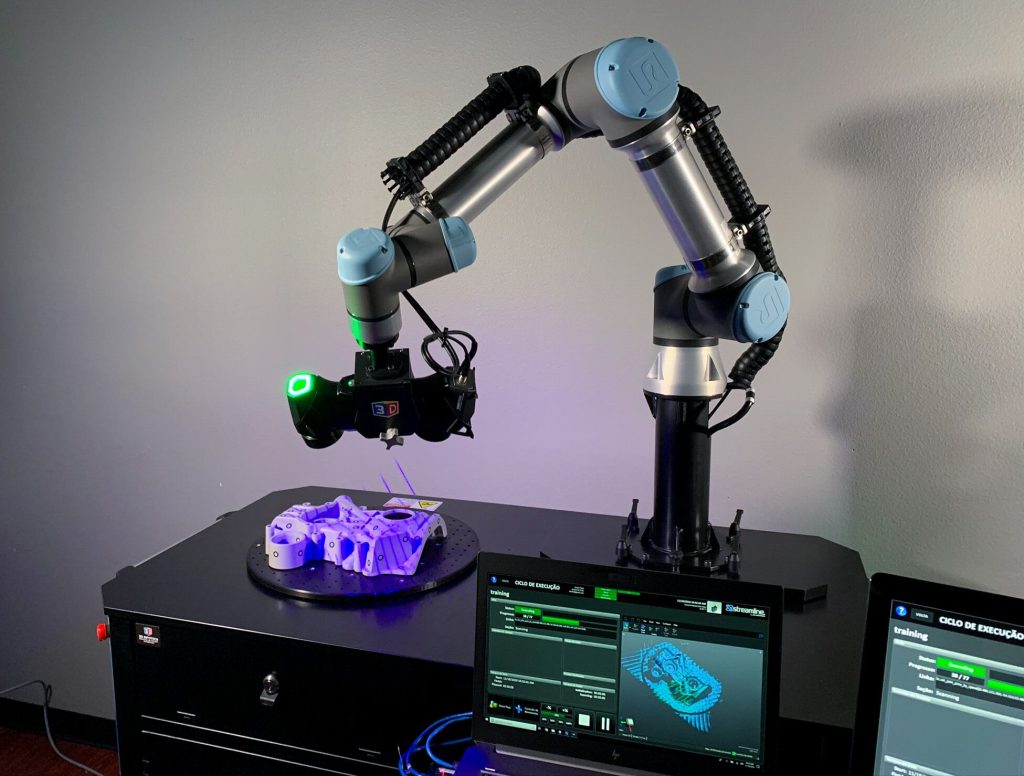

Many manufacturers are still using hand tools like calipers, micrometers or height gages for parts measurement, causing problems with consistency and measurement for complex geometries. 3D scanning provides a more comprehensive inspection report for in-process and final verification for a wide variety of industries. To automate this process, 3D Infotech has developed the UMA Smart Station, a standardized system integrated with Universal Robots collaborative robots.

Many manufacturers are still using hand tools like calipers, micrometers or height gages for parts measurement, causing problems with consistency and measurement for complex geometries. 3D scanning provides a more comprehensive inspection report for in-process and final verification for a wide variety of industries. To automate this process, 3D Infotech has developed the UMA Smart Station, a standardized system integrated with Universal Robots collaborative robots.

Driven by 3D Infotech's Streamline software, the UMA station allows for the adding of 3D scanners to the end of UR3e, UR5e and UR10e cobot arms for advanced scan-to-CAD comparison and inspection capabilities, including GD&T (geometric dimensioning and tolerancing).

A UMA station customer, Royal Technologies, needed to scan a wide range of parts. "Some operators would miss certain features of the part, resulting in bad parts, now we catch anything that is deviated. To summarize, it has improved speed, quality, and overall performance," said Trevor Lipsey, launch coordinator at Royal Technologies.