Contact Details

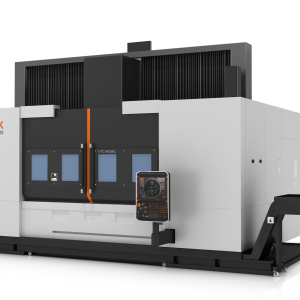

Mazak Corp.'s VCN-575C vertical machining center brings advanced technology, performance and value to heavy-torque machining applications. Made in Kentucky, the machine features a traditional C-frame design, vibration damping, rigid base and headstock/column castings for extreme stability.

A high-torque 50-taper spindle gives the machine the strength and power for aggressive metal removal in tough-to-machine materials. The 30-hp spindle delivers speeds up to 6,000 rpm.

The VCN-575C is a standard single-table 3-axis machine with an optional 4th-axis NC rotary table. With table right/left dimensions of 51.180" (1300 mm) and height of 22.440" (570 mm), the machine easily handles medium to large workpieces. Plus, a fast traverse rate of 1,654 ipm in the X, Y and Z axes, which measure 41.34" (1,050 mm); 22.44" (570 mm) and 20.08" (510 mm) respectively, contributes to the machine’s productivity.

The VCN-575C comes standard with a 24-tool magazine, and the machine’s high-speed automatic toolchanger (ATC) is servo-driven for fast and reliable operation. Tool changes occur in 5.2 seconds to significantly reduce non-cut times and get spindles back in the cut in the shortest times possible. Such speed is possible because the ATC always takes the quickest route to the next needed tool position.

The VCN-575C is equipped with the Mazatrol SmoothG CNC. The innovative programming, performance and monitoring functions, as well as the ability to use both EIA/ISO and conversational programming bring optimal speed and accuracy to complex part production. Advanced hardware – including a pivoting CNC panel and intuitive, 19" multiple-touch LCD control screen – allows for complete ease of use, while an optional CFast memory card can store up to 32GB of program data.

To enhance productivity even further through increased uptime and lights-out production, the VCN-575C seamlessly integrates with a wide range of automation solutions.

Related Glossary Terms

- automatic toolchanger

automatic toolchanger

Mechanism typically included in a machining center that, on the appropriate command, removes one cutting tool from the spindle nose and replaces it with another. The changer restores the used tool to the magazine and selects and withdraws the next desired tool from the storage magazine. The changer is controlled by a set of prerecorded/predetermined instructions associated with the part(s) to be produced.

- computer numerical control ( CNC)

computer numerical control ( CNC)

Microprocessor-based controller dedicated to a machine tool that permits the creation or modification of parts. Programmed numerical control activates the machine’s servos and spindle drives and controls the various machining operations. See DNC, direct numerical control; NC, numerical control.

- conversational programming

conversational programming

Method for using plain English to produce G-code file without knowing G-code in order to program CNC machines.

- inches per minute ( ipm)

inches per minute ( ipm)

Value that refers to how far the workpiece or cutter advances linearly in 1 minute, defined as: ipm = ipt 5 number of effective teeth 5 rpm. Also known as the table feed or machine feed.

- machining center

machining center

CNC machine tool capable of drilling, reaming, tapping, milling and boring. Normally comes with an automatic toolchanger. See automatic toolchanger.

- numerical control ( NC)

numerical control ( NC)

Any controlled equipment that allows an operator to program its movement by entering a series of coded numbers and symbols. See CNC, computer numerical control; DNC, direct numerical control.

- toolchanger

toolchanger

Carriage or drum attached to a machining center that holds tools until needed; when a tool is needed, the toolchanger inserts the tool into the machine spindle. See automatic toolchanger.

PRODUCTS

PRODUCTS