Contact Details

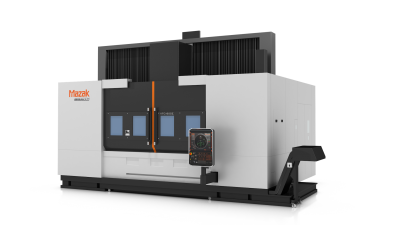

The Mazak VTC-805E vertical traveling-column machining center brings high versatility and productivity to those shops that need to tackle long and/or heavy parts. The machine combines an increased Y-axis stroke, long bed/table size, high spindle speed and torque and Mazak’s new SmoothG CNC for efficient, powerful machining, according to the company.

For manufacturers that need as much Y-axis travel as possible, the VTC-805E provides an extended Y-axis travel of 32" as a cost-effective alternative to a bridge-style machine. The machine’s fixed table measures 82.7" x 32.3" (2100mm x 820mm), while its moving column design provides a 69.3" X axis and 28.3" Z axis.

With an optional center partition, it is possible to transform the VTC-805E’s table into two separate work areas to process parts on one side, while operators load/unload parts on the other for an overall reduction in cycle times. A special turret-style magazine accommodates 40 tools for longer periods of uninterrupted production, as well as for more part-processing versatility.

Mazak equipped the VTC-805E with a 30-hp, CAT 50-taper, 6,000-rpm spindle that easily tackles a variety of materials including titanium, aluminum, steel and cast iron. And for even more power and speed, Mazak offers an optional 40-hp, CAT 50-taper, 10,000-rpm spindle.

The VTC-805E features the new MAZATROL SmoothG CNC that makes it easy to generate programs for off-centerline machining as well as angled drilling, milling and tapping operations. Several innovative programming, performance and monitoring functions bring optimum speed and accuracy to complex part production. Advanced hardware including a tilting CNC panel and intuitive, multi-touch control screen allows for complete ease of use, while an SD card stores up to 32GB of program data.

Related Glossary Terms

- computer numerical control ( CNC)

computer numerical control ( CNC)

Microprocessor-based controller dedicated to a machine tool that permits the creation or modification of parts. Programmed numerical control activates the machine’s servos and spindle drives and controls the various machining operations. See DNC, direct numerical control; NC, numerical control.

- gang cutting ( milling)

gang cutting ( milling)

Machining with several cutters mounted on a single arbor, generally for simultaneous cutting.

- machining center

machining center

CNC machine tool capable of drilling, reaming, tapping, milling and boring. Normally comes with an automatic toolchanger. See automatic toolchanger.

- milling

milling

Machining operation in which metal or other material is removed by applying power to a rotating cutter. In vertical milling, the cutting tool is mounted vertically on the spindle. In horizontal milling, the cutting tool is mounted horizontally, either directly on the spindle or on an arbor. Horizontal milling is further broken down into conventional milling, where the cutter rotates opposite the direction of feed, or “up” into the workpiece; and climb milling, where the cutter rotates in the direction of feed, or “down” into the workpiece. Milling operations include plane or surface milling, endmilling, facemilling, angle milling, form milling and profiling.

- tapping

tapping

Machining operation in which a tap, with teeth on its periphery, cuts internal threads in a predrilled hole having a smaller diameter than the tap diameter. Threads are formed by a combined rotary and axial-relative motion between tap and workpiece. See tap.

PRODUCTS

PRODUCTS