Contact Details

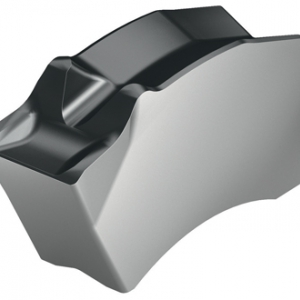

Walter has expanded the capabilities of its popular Walter BLAXX M3024 heptagon milling cutter with new wiper inserts. The inserts, which have two right-hand and two left-hand cutting edges, were specifically developed for the Walter BLAXX M3024, and allow it to be used for finishing operations.

Semifinishing and finishing operations can now be combined into a single operation using a single tool – without adjusting the finishing cutting edges. This reduces the number of tools required and reduces machining time by minimizing time spent changing and adjusting tools.

This combination of milling cutter and indexable inserts is well-suited to the multiple-step production of components such as exhaust turbochargers or turbine blades, as well as any other components made from stainless steels, cast materials or steel. Additional features of these new negative indexable wiper inserts include excellent process reliability and soft cutting action due to the positive cutting edge geometry.

Designated as wiper insert XNGX0705ANN-F67, they may only be combined with periphery ground inserts XNGU0705ANN with secondary cutting edge. Additionally, to achieve similar results, Walter has provided wiper insert LNHX13068R-L55T for use with its F5141 indexable facemill. This insert has four right-hand cutting edges and may only be combined with periphery ground inserts LNHU13068R-L55T.

Related Glossary Terms

- facemill

facemill

Milling cutter for cutting flat surfaces.

- gang cutting ( milling)

gang cutting ( milling)

Machining with several cutters mounted on a single arbor, generally for simultaneous cutting.

- milling

milling

Machining operation in which metal or other material is removed by applying power to a rotating cutter. In vertical milling, the cutting tool is mounted vertically on the spindle. In horizontal milling, the cutting tool is mounted horizontally, either directly on the spindle or on an arbor. Horizontal milling is further broken down into conventional milling, where the cutter rotates opposite the direction of feed, or “up” into the workpiece; and climb milling, where the cutter rotates in the direction of feed, or “down” into the workpiece. Milling operations include plane or surface milling, endmilling, facemilling, angle milling, form milling and profiling.

- milling cutter

milling cutter

Loosely, any milling tool. Horizontal cutters take the form of plain milling cutters, plain spiral-tooth cutters, helical cutters, side-milling cutters, staggered-tooth side-milling cutters, facemilling cutters, angular cutters, double-angle cutters, convex and concave form-milling cutters, straddle-sprocket cutters, spur-gear cutters, corner-rounding cutters and slitting saws. Vertical cutters use shank-mounted cutting tools, including endmills, T-slot cutters, Woodruff keyseat cutters and dovetail cutters; these may also be used on horizontal mills. See milling.

- stainless steels

stainless steels

Stainless steels possess high strength, heat resistance, excellent workability and erosion resistance. Four general classes have been developed to cover a range of mechanical and physical properties for particular applications. The four classes are: the austenitic types of the chromium-nickel-manganese 200 series and the chromium-nickel 300 series; the martensitic types of the chromium, hardenable 400 series; the chromium, nonhardenable 400-series ferritic types; and the precipitation-hardening type of chromium-nickel alloys with additional elements that are hardenable by solution treating and aging.

- wiper

wiper

Metal-removing edge on the face of a cutter that travels in a plane perpendicular to the axis. It is the edge that sweeps the machined surface. The flat should be as wide as the feed per revolution of the cutter. This allows any given insert to wipe the entire workpiece surface and impart a fine surface finish at a high feed rate.

PRODUCTS

PRODUCTS