Contact Details

Tungaloy has introduced ten new XVCT-AM square shoulder milling inserts to expand its TungAluMill line designed specifically for non-ferrous applications.

TungAluMill is intended for efficient machining of aluminum alloys and other non-ferrous materials at high speed rates. The tool is designed to eliminate radial insert displacement caused by heavy cutting forces and strong centrifugal forces during high-speed rotation of the cutter, which is essential for efficient machining of aluminum parts. Additionally, the insert's top and peripheral surfaces are ground and polished to a mirror-like finish, resulting in high-positive and sharp cutting edges that ensure soft cutting action, good surface finishing quality, and prevention of built-up edge formation on the cutting edge.

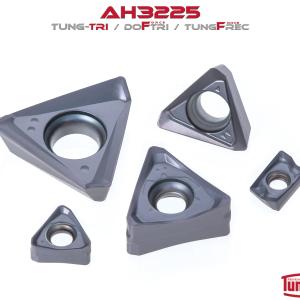

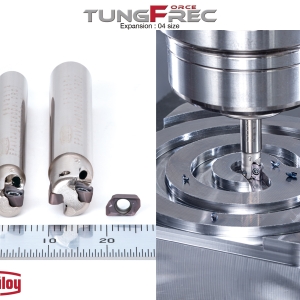

Built on the proven features of the conventional XVCT-AJ inserts, the new XVCT-AM inserts introduce an enhanced interface design. This design improves insert retention during high-speed machining while reducing raw material usage for insert production, all without compromising superior cutting performance.

Related Glossary Terms

- alloys

alloys

Substances having metallic properties and being composed of two or more chemical elements of which at least one is a metal.

- aluminum alloys

aluminum alloys

Aluminum containing specified quantities of alloying elements added to obtain the necessary mechanical and physical properties. Aluminum alloys are divided into two categories: wrought compositions and casting compositions. Some compositions may contain up to 10 alloying elements, but only one or two are the main alloying elements, such as copper, manganese, silicon, magnesium, zinc or tin.

- built-up edge ( BUE)

built-up edge ( BUE)

1. Permanently damaging a metal by heating to cause either incipient melting or intergranular oxidation. 2. In grinding, getting the workpiece hot enough to cause discoloration or to change the microstructure by tempering or hardening.

- gang cutting ( milling)

gang cutting ( milling)

Machining with several cutters mounted on a single arbor, generally for simultaneous cutting.

- milling

milling

Machining operation in which metal or other material is removed by applying power to a rotating cutter. In vertical milling, the cutting tool is mounted vertically on the spindle. In horizontal milling, the cutting tool is mounted horizontally, either directly on the spindle or on an arbor. Horizontal milling is further broken down into conventional milling, where the cutter rotates opposite the direction of feed, or “up” into the workpiece; and climb milling, where the cutter rotates in the direction of feed, or “down” into the workpiece. Milling operations include plane or surface milling, endmilling, facemilling, angle milling, form milling and profiling.

PRODUCTS

PRODUCTS