April 2015

Articles in this issue

Tooling that quickly boosts profits

Quick-change tooling can boost profits.

How flame straightening works

How flame hardening works

Cut the clamp

Increase part quality and productivity when deep-cavity micromachining while achieving tight tolerances. A heat-activated, wax-based compound for holding parts.

Chuck aids retention knob work

Enhance precision and shorten changeover time when machining retention knobs. Quick-change collet chucks.

Keeping your distance

Keeping employees' personal matters separate from professional ones.

Cut the chatter

Methods for minimizing chatter.

A cool break

A PCD milling cutter that combines a patented chipbreaker and direct cooling through the cutting face.

A layered approach

A new process for strengthening metals while making them more resistant to corrosion.

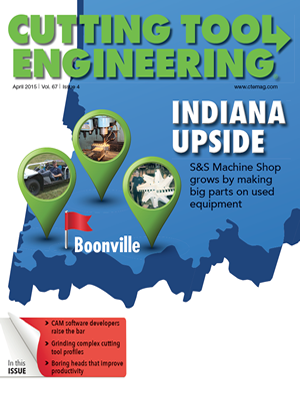

Vertically aligned

Vertical machining centers play a central role in the growth of S&S Machine Shop.

CAM it up

Software developers raise the bar with improved toolpaths, integration and simulation.

Professional profiles

When grinding complex cutting tool profiles, attention should be paid to the software, the wheel and the tool blank for best results.

Productivity-boosting boring heads

Boring heads that improve productivity.

Consider live tooling when purchasing a machine

When shops purchase new machinery, a common error some make is accepting the standard live tooling package from the builder without considering other options. …

Battling part barreling

Dr. Jeffrey Badger, who authors the Ask the Grinding Doc column, answers questions about barreling and scrubber nozzles.