Fill up with high-density workholding

Fill up with high-density workholding

High-density workholding offers many benefits, a prime one being the ability to run a machine tool longer unattended.

Metalworking professionals understand the importance of keeping machine tool spindles rotating as much as possible and overcoming labor shortages by enabling operators to run more than one machine or perform other duties while continuing to create chips. One way to achieve these goals is with high-density workholding, which calls for as many workpieces as reasonably possible to be placed in a machine work envelope, said David Bishop, general manager of Mitee-Bite Products LLC in Center Ossipee, New Hampshire.

"Compared to single part loading, it virtually removes the labor cost and reduces the cost per piece when factoring tool changes, etc.," he said about high-density workholding and how one cutting tool can go rapidly from part to part rather than changing tools constantly. "I like to say it levels the playing field globally."

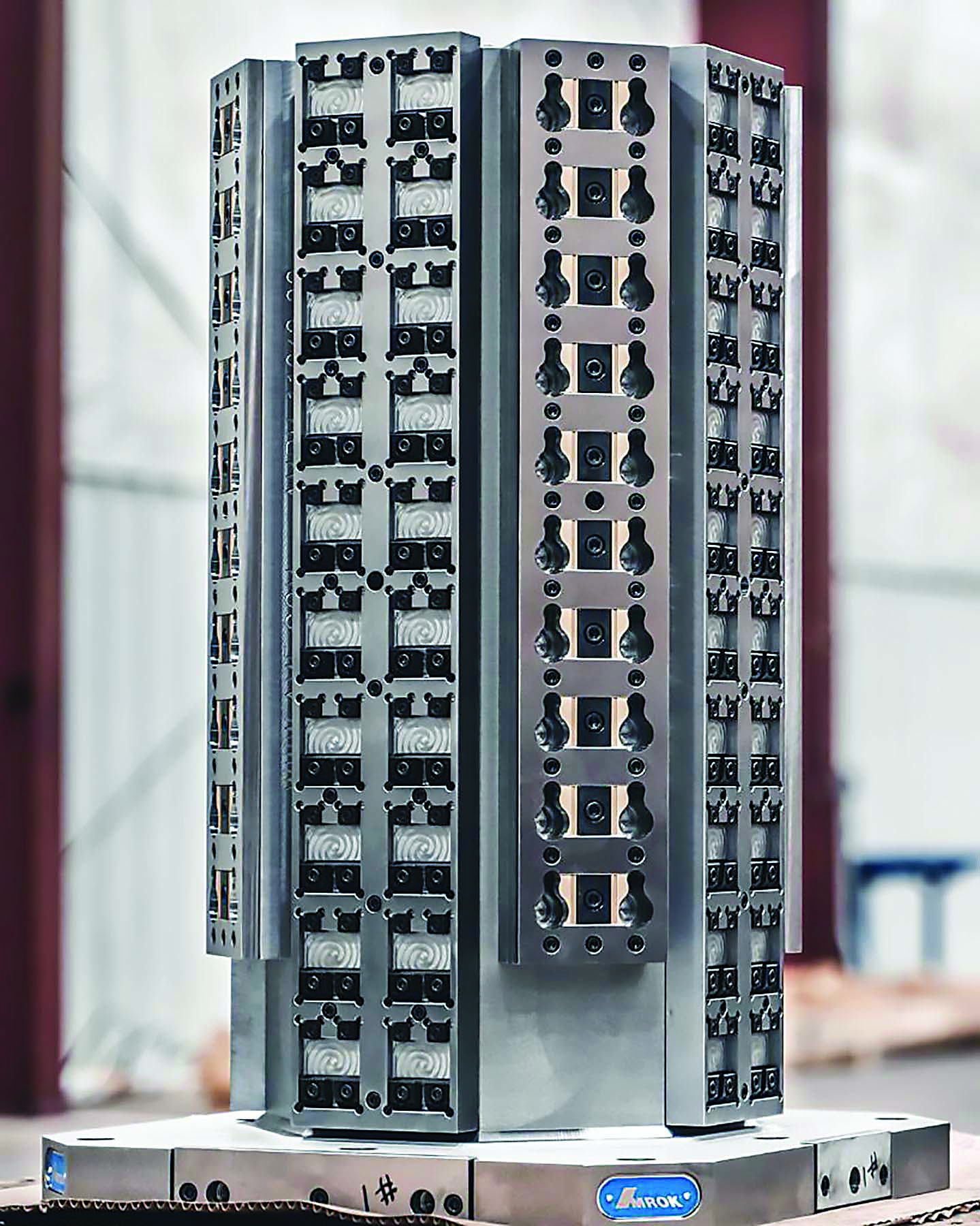

An example of high-density workholding using a multiple-sided tombstone for a horizontal machining center in which labor cost is removed. Image courtesy of Mitee-Bite Products

Depending on the application, Mitee-Bite produces a variety of products to enable high-density workholding, such as the Uniforce clamp with a steel wedge that spreads the clamping force uniformly on both sides of the aluminum channel, and the low-profile, modular Pitbull clamps that exert a positive down force.

"The majority of our items can be used for high-density applications," Bishop added, noting that the company's engineers help determine how many parts can be held under or in front of the spindle and the options available to do so. "I hate being sold anything, so none of our guys sell. We provide options and let the customer make the decision."

Many applications have straight-forward solutions, but Bishop said he prefers tackling ones that are more challenging. "It's the main reason we have so many styles of fixturing clamps. It's limited only by your imagination and creativity."

Pack Them In

Advanced Machine & Engineering Co. is another source for devices that enable end users to take full advantage of a machine's work envelope. "We can maximize that envelope based on the machine size and capacity," said Kaleb Mertz, business development leader for the Rockford, Illinois-based company.

AME supplies Mitee-Bite products, but is "brand agnostic," according to Mertz, and also offers workholders from Schunk, Triag International, 5th Axis and trunnion tables from Martin Manufacturing. "The benefit that we have is we're very well known for our tombstones and grid plates."

In addition to workholders, AME offers an array of machining products and performs contract manufacturing services.

One example of high-density workholding integrates Mitee-Bite Uniforce clamps onto an octagon tombstone, Mertz explained.

"It's all about runtime," added Nick Rupprecht, engineering manager at AME. "The more parts you can stack on the eight faces, the better the time in which the fixture is going to be staying in the machine."

He noted that scenario is especially advantageous when a minimal number of machined features are required, such as drilling a hole in a part's face and side. "Imagine if you had to change out that part every time it was completed."

High-density workholding is essential to effectively satisfy high-production demands, according to Mertz. "If you're a shop that runs three shifts and weekends, then you're going to get a lot less out of loading one part at a time versus having a high-density fixture where you have a lot less door-open-and-close time."

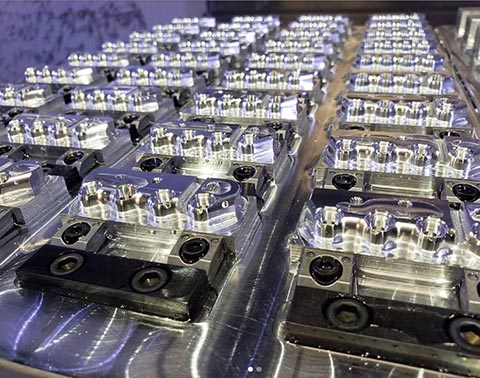

Mitee-Bite says its Pitbull clamps have an extremely low bite and exert a positive down force. In this example, each clamp produces 3,600 lbs. of pressure. Image courtesy of Mitee-Bite Products

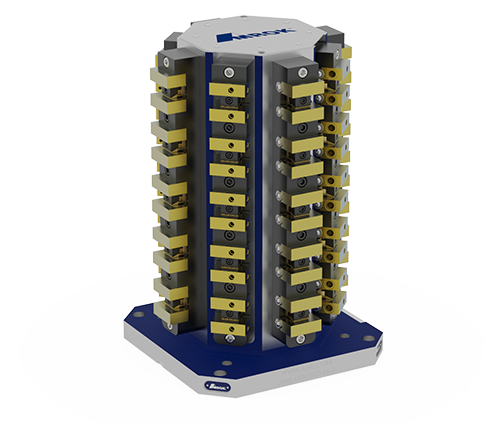

High-density workholding is suitable even for job shops that typically see a high mix of parts, Mertz said. For that scenario, one approach is to incorporate modular workholders into a high-density design. For example, AME offers Amrok fixture plates with the

rail-based powerCLAMP 3D-modular workholding system from Triag and AME precision locating screws. Different types of mounting modules can be located anywhere on the rails, and the variety can include three-jaw chucks, collet chucks, miniature self-centering vises, magnetic clamps and vacuum clamps.

"You have a quick changeover and still have that density," he said, conceding that programming considerations might limit how varied the part mix is.

Removing Idle Time

A pallet changer is not mandatory to enable high-density workholding, but it is if the goal is to maximize machine capability and eliminate as much idle spindle time as possible, Mitee-Bite's Bishop said. "I'd rather see an operator waiting on a machine than a machine waiting on an operator."

He noted that one manufacturer of electrical connectors was able to move production from China to the U.S. after experiencing quality and shipping delay issues by outfitting two Haas machines with Mitee-Bite automatic pallet changers set up with a carrier method. Uniforce clamps were also part of the arrangement. "They came out with finished parts, and they made them 70 cents cheaper than China — and they saved a million dollars a year."

In addition to reducing the cost per part, an automatic pallet changer enables a part manufacturer to perform lights-out, or unattended, machining, Bishop said. "You could even load up two pallets before you go home, and you come in and it's just finishing up. "So, you just got another day out of it, and you weren't even there."

Running unattended is especially beneficial on horizontal machining centers with pallet pool systems, he added. "Those are designed to run lights out and that's really where we shine, because as expensive as those are the owner wants to make sure they're getting the most efficiency or productivity out of that."

If a pallet system is not available, Rupprecht recommends using a quick-change workholding system to minimize the time the spindle is idle. One option is the Schunk Vero-S modular, quick-change pallet system, which is a zero-point clamping system that can be integrated into a tombstone. With a quick-change system, the time the spindle sits idle is likely about a minute or two versus 15 to 20 minutes when loading parts manually.

An Amrok pallet outfitted with Mitee-Bite Uniforce clamps is just one example of a high-density workholding configuration. Image courtesy of Advanced Machine & Engineering

While high-density workholding frequently involves relatively small workpieces positioned efficiently on a tombstone or trunnion table, large workpieces on a grid plate in a large gantry machine with a table size of 2 m × 6 m (78.7" × 236.2"), for instance, also qualifies, Mertz noted.

"Sometimes we split the plates up," Rupprecht added.

Check It Out

High-density workholding offers many benefits, but Bishop noted that it is sometimes easier to just hold one part at a time, depending on how complex the part is and if the machine must be stopped occasionally to do in-process inspections. To determine if an application is appropriate for a high-density approach, Mitee-Bite provides a return-on-investment calculator on its website. "You can check your application, how many parts you're running, how long it would take to build your fixture and the cost of your clamps versus opening and closing the door X amount of times."

How long it takes for a manufacturer to achieve a payback varies but it can be quick. "I've seen guys get their money back their first run," he said, "and there are times that they may have to run it two or three times. It depends on which clamps they're using."

In addition to providing automated pallet delivery with equipment from Trinity Robotic Automation, AME partners with RoboJob-USA to integrate robot machine tending into an operation. Rupprecht noted, however, that robot loading of a single part is basically the opposite of high-density workholding, but it has its place. "You will have only one fixture and the part is being brought in by a robot fairly quickly."

Mertz added, "You're only running one shift and you want to maximize that, so on that second and third shift you could potentially robot load parts and gain a lot. In the end, it's really about throughput."

Cutting Production Cost with Quick-Change Pallet System

Haydon Kerk Motion Solutions Inc. is a leading manufacturer of drive systems. As a provider of high-performance motion solutions for military, aerospace, industrial and medical applications, the pressure is high for the Waterbury, Connecticut-based company to produce high-quality parts as quickly as possible.

To improve product quality and turnaround time while cutting costs, Haydon Kerk began to manufacture previously outsourced parts on a Haas VF-2SS vertical mill, beginning with motor housings. About 8,000 of those parts are needed annually. However, the development and implementation of new processes such as cutting tool selection, workholding design and manufacturing, and CNC machine programming inevitably led to a delay in product output.

The first side is completed in this strip of parts. Inset: Finished test parts. Image courtesy of Mitee-Bite Products

The company first fixtured the motor housings on a subplate bolted to the machine table, which left the machine sitting idle while the parts were swapped. To minimize downtime, just 10 parts per load were fixtured, a fraction of the possible density the mill offered. While it was clear to Haydon Kerk that it needed a more efficient system to meet the production schedule, the company struggled to find a solution that would not be costly and further disrupt production.

To gain an outside perspective, Haydon Kerk contacted Eric Meehan, president of the W.K. Coleman Co. in North Kingstown, Rhode Island, a manufacturers' representative that serves New England. After visiting Haydon Kerk to examine the shop setup and discuss potential improvements, he determined that the Quick Change Receiver from Mitee-Bite Products LLC was "the best tool for the job."

By facilitating the rapid change of compact 378.5 mm × 378.5 mm (14.9" × 14.9") fixtures, it was clear how the Mitee-Bite system would allow Haydon Kerk to keep its milling machine running almost constantly. As a result, Haydon Kerk produces 66 motor housing parts per pallet — a 600% increase in part density.

The parts previously cost Haydon Kerk $16.50 each when outsourced. However, when manufactured in-house, they cost only $4.00 each, including materials and anodizing, saving roughly $118,000 a year.

In addition to the Quick Change Receiver, Mitee-Bite supplied the expansion pins, locating rails and clamps used to fixture the parts to the first and second operation pallets. The clamps measure 19.05 mm × 19.05 mm (¾" × ¾") and exert up to 1,633 kg (3,600 lbs.) of pressure.

According to David Loukides, lead milling machinist at Haydon Kerk, purchasing these components also increased the mill's capacity to manufacture other parts. He said that in the future, "there will be a minimum of 20 more parts brought back in-house, or until the mill reaches its max capacity on two shifts."

Haydon Kerk plans to use the Quick Change system to make that transition as smooth as possible.

—Callie McIntyre