The fundamentals of industrial sawing

The fundamentals of industrial sawing

Sawing is one of the most common manufacturing processes in a machine shop. It is versatile, simple and reliable. Nonetheless, many young engineers and machinists are quite familiar with lasers and abrasive waterjets but have no knowledge of sawing.

Extracting computer-generated shapes from CNC machines with high-pressure water and high-energy lasers can be appealing, making it is easy to forget about more-traditional cutting methods such as sawing.

Sawing is one of the most common manufacturing processes in a machine shop. It is versatile, simple and reliable. Nonetheless, many of the young engineers and machinists I meet are quite familiar with lasers and abrasive waterjets but have no knowledge of sawing. Sawing may be less interesting than some machining technologies, but it is still a vital machining operation.

Sawing equipment falls into four basic categories: bandsaws, hacksaws, circular saws and abrasive saws. Each type has its place in manufacturing and, when applied correctly, is efficient and effective.

The Omnipresent Bandsaw

Toolmakers and machinists are probably most familiar with bandsaws, which are found in machining environments ranging from one-off and low-volume tool shops to high-production automotive manufacturers. They are the most-versatile and cost-effective style of saw. And, compared to other types of saws, they can cut a broader range of material types and feature sizes. They provide a wider range of cutting speeds and feed rates and are also reasonably accurate and repeatable.

This vertical saw has several attachments to assist cutting, such as the miter attachment shown on the saw table. All images courtesy of C. Tate.

Bandsaws come in two styles: horizontal and vertical. Construction is similar for both styles, but the blade orientation provides distinct advantages, depending on the application.

A horizontal bandsaw presents the saw blade to the workpiece in a plane that is parallel to the floor. Because of the approach angle of the blade, a horizontal saw is well-suited for cutting long materials, such as bar, tube, pipe and structural shapes, to the desired lengths.

In contrast, a vertical bandsaw presents the blade to the workpiece in a plane that is perpendicular to the floor. It is best-suited for cutting shapes from flat materials, like plates and sheets.

The traditional vertical saw is manually operated. Therefore, it is well-suited for cutting shapes out of plates. While not impossible, it is improbable that an automatic saw would be used to rough components before machining. Manual saws are more suitable for this activity in toolrooms because of low part volumes. Other methods, possibly waterjetting, would be used for similar tasks in a production setting.

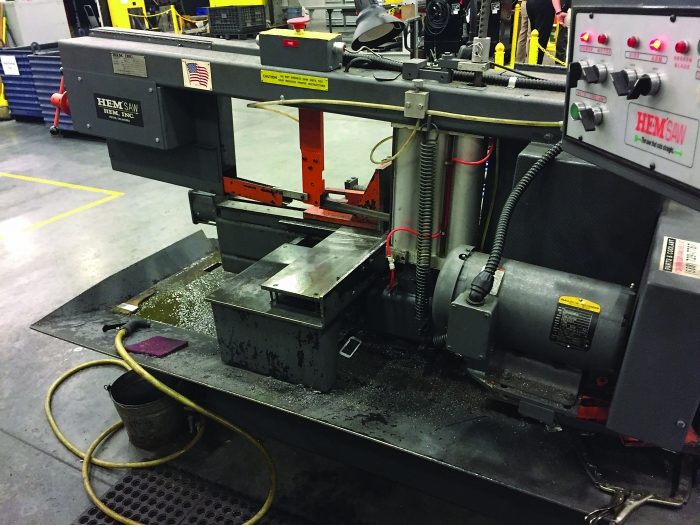

At Mitsubishi's valve shop, this horizontal bandsaw is used more than the shop's two other saws.

More-complex versions, which are often automated, usually with a CNC, are called "plate saws." These saws have large tables that are capable of accommodating entire plates from which smaller pieces are cut. Many metal suppliers employ plate saws to cut square, rectangular and odd-shaped pieces of tool steel. In addition, some manufacturers use plate saws to cut blanks that are then machined.

Aerospace manufacturers often use plate saws in applications where thermal cutting, such as plasma arc or laser, can create heat-affected zones that compromise the mechanical properties of the material.

Vertical saws can cut bars, shapes and tubes. However, they are not typically configured with the same type of clamping mechanisms as horizontal saws, which have clamps that work much like a vise. The workpiece is clamped between one stationary jaw and one movable jaw. Horizontal saws hold the material stationary and pass the blade through the material during the cut, whereas vertical saws must move the material into the blade. Because horizontal saws hold the material stationary, they are better-suited for cutting long, thin pieces of bundled material like pipes and bar stock. Conversely, a vertical design economically provides the capacity to saw large plates; a horizontal capable of sawing large plates would not be economical to build.

Kin to the horizontal bandsaw is the power hacksaw. Bandsaws have driven the power hacksaw to the brink of extinction; finding a new hacksaw is difficult. Hacksaws are simple machines. They have the same configuration as bandsaws but incorporate a reciprocating motion to make the cut. They are effective but slow.

Circular Reasoning

Circular saws, also known as cold saws, are excellent choices for achieving accurate cuts. Stiff blades and rigid ways stabilize the saw, allowing exceptional miter joints and very square ends.

Cold saws owe their accuracy to their construction, which is similar to a milling machine, where a carriage with a motor and blade ride on a set of ways mounted to a sturdy column. Cold saws are an excellent choice for shops that must produce very accurate geometries for welding fabrication or where the cut end must have a fine finish.

Manually operated cold saws are very compact. Their size makes them ideal for small tool shops or cramped work areas. Cold saws are also suitable for production work. The disadvantage of a cold saw, compared to a bandsaw, is its limited capacity. Dollar for dollar, the bandsaw can cut much larger material. A cold saw is limited to workpieces that can fit between the edge of the blade and arbor where the blade mounts; bandsaws do not have this limitation.

This large abrasive saw is for roughing large channels, angle iron and similar applications.

High-quality finishes are a result of blades that are constructed of HSS with ground teeth or brazed carbide, which are for cutting nonferrous material. The blades are basically large milling tools. They can be manufactured with many different tooth pitches.

These blades also make a cold saw ideal for difficult-to-cut materials, such as thin-walled tubing and soft, gummy plastics.

Barbaric Blades

No sawing discussion would be complete without covering abrasive cutoff saws. As the name implies, these saws utilize blades made from abrasives, usually aluminum oxide encapsulated in a fiber-reinforced resin.

Compared to the other saws discussed, abrasive saws are barbaric. They are hot, dirty and not highly accurate, but they do have a place in manufacturing.

Abrasive saws are easy to use and require little maintenance. They don't need coolant and are economical to operate. These saws are often found in places that need to quickly cut something long down to size.

Abrasive saws are also used to remove sprues, gates and slag from forgings and castings. They are often found in shops that fabricate rebar. Abrasive saws and blades are forgiving, which makes them suitable for harsh

environments.

Sawing is a basic machining process, one that is used in manufacturing most metal products. But unlike turning and milling, where new products are constantly released, sawing has seen relatively few innovations. This is evidence that sawing has been, and continues to be, an efficient, robust and reliable process.