Getting a chatter diagnosis

Getting a chatter diagnosis

Puzzled by the appearance of a choppy, spiral-shaped set of chatter marks showing up on a workpiece, a shop sought a diagnosis from Jeffrey Badger, Ph.D., who writes the Ask the Grinding Doc column in Cutting Tool Engineering.

Dear Doc: I'm getting a bizarre type of chatter marks on a workpiece, sort of spiral-shaped but sort of choppy. There's a pattern that creates an angle. But if I slightly change the wheel rpm, that angle will change. Any idea what this is?

The Doc Replies: Chatter is the most maddening subject of not only grinding but machining in general. That is because there are hundreds of potential causes. Even Frederick Winslow Taylor (1856-1915), the father of production engineering, said, "Chatter is the most obscure and delicate of all problems facing the machinist."

It sounds to me like you're experiencing "fish-scale chatter," which can occur in stationary dressing (single point, cluster, blade) or traverse diamond disc dressing. (It doesn't typically occur in plunge-roll dressing.)

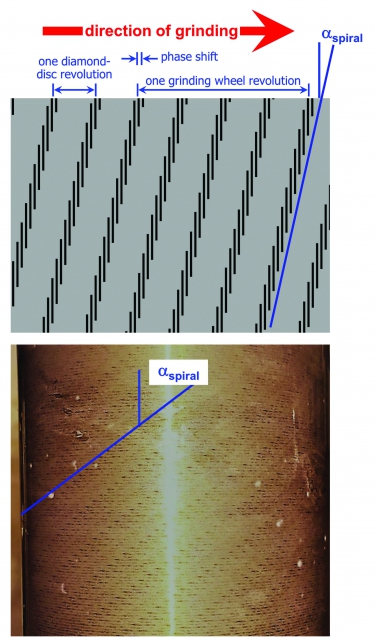

Theoretical fish-scale chatter pattern (top) and actual fish-scale chatter

on a round workpiece (bottom). Image courtesy of J. Badger

Fish-scale chatter occurs when the traversing diamond makes intermittent contact with the grinding wheel, generating high points on the wheel. The most common cause that I see in production is when using a diamond dressing disc with excessive runout. If the disc is running at 12,000 rpm and the wheel at 2,900 rpm, every time the wheel makes one revolution, the roll makes 4.14 revolutions. That leaves four high points on the wheel.

But here's where it gets tricky. That 0.14 portion of the 4.14 means that the next time the wheel makes a revolution, the runout on the disc hits slightly downstream on the wheel, creating a "phase shift." As you move down the width of the wheel, you still have about four high points per revolution, but those high points are shifted circumferentially. And this creates that strange fish-scale pattern. Change the wheel rpm to 2,800, and the ratio is 12,000/2,950, or 4.068. Now the phase shift is smaller, and the slope of the diagonal pattern (αspiral in the figure), which also depends on the ratio of wheel surface speed to workpiece surface speed when grinding, will be less.

If you didn't get all that, don't worry. It took me a while to get my head around fish-scale chatter. The important point is the solution, which is to fix that intermittent contact. If your diamond disc has runout, fix it. If your stationary diamond is loose and bouncing during dressing, stiffen it.