Learn not to burn

Learn not to burn

Jeffrey Badger, Ph.D., fields a question from a shop getting "terrible burn on the shoulder" when cylindrical grinding steel parts with a straight plunge.

Dear Doc: I cylindrical-grind steel parts with a straight plunge and get terrible burn on the shoulder. The machine isn't capable of rotating the wheelhead 30°. What can I do to solve the burn problem?

The Doc Replies: Not much. When you do a straight plunge with a wheel that doesn't swivel, the side of the wheel does nothing but rub the shoulder. Even if you do a vector feed, the side is still just going to rub—there's no way around it.

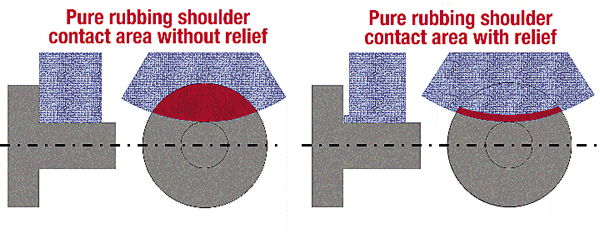

There are, however, a few things you can do to somewhat cope with the situation. First, aim a dedicated coolant nozzle directly at the shoulder/wheel interface and deliver high-pressure coolant to the interface. Second, relieve the side of the wheel by dressing a small depth, such as 0.025mm, about 1mm to 2mm from the OD. Do this up the side of the wheel, but leave that relief 1mm to 2mm from the wheel OD to grind the workpiece OD. This reduces the contact area and friction on the shoulder. (See figure 1 below.)

Figure 1.

Third, dress the side of the wheel that's not relieved as fast as you can. You can get away with this because many applications have more liberal surface finish requirements on the shoulder. And even if your application doesn't, all that rubbing will impart a fine surface in spite of the sharp dress. Finally, increase the workpiece rpm and reduce the wheel speed; be aware, though, that these actions will increase wheel wear.

Dear Doc: I cylindrical-grind hardened steel workpieces. This involves cutting, polishing and etching them to check for "white layer." However, I worry that when using a standard, manual cutoff wheel, I may be inducing burn. What can I do?

The Doc Replies: There are options. If you're using coolant when cutting off, have an operator grind the workpiece a bit, pull back to allow the coolant to quench the workpiece, grind a little more, then pull back to allow the coolant to quench again.

In addition, after you've cut off the workpiece, mount it on a surface grinder with the potentially burned side facing up. Slowly grind 0.40" to 0.080" to remove any material you might have burned while cutting off, then polish and etch as usual.

Dear Doc: I grind tungsten-carbide parts and just got a machine with an automatic sticker to remove loading. Now I can't "stick by feel" and have no idea what sticking feed rate to use. Any ideas?

The Doc Replies: Assuming your plunging directly into the wheel OD, which is the best way to do it, here's a starting point: Multiply the wheel speed in m/sec. by 15 to get a sticking feed rate in mm/min. So, if the wheel is running at 10 m/sec. during sticking, stick at 150 mm/min. (10×15). After that, monitor the spindle power during grinding. When the wheel loads, stick it.

If power doesn't drop to near the unloaded level, the sticking feed rate is too low. Use the lowest sticking feed rate that drops power to near the unloaded level.