Lift-assist devices do the heavy work

Lift-assist devices do the heavy work

Whether heavy, tall, light or small, lifting and moving parts can be a challenge.n

Each day, workers across the entire manufacturing supply chain lift, transport and position a plethora of parts, raw materials, components, finished assemblies and more. These workloads are often hefty and awkward, thin and wobbly, top-heavy or experiencing some other center-of-gravity issue. Placing the objects where they are needed may require personnel to twist their bodies or reach out or up with their arms. They may perform the task all day. This effort can be exhausting and even harmful.

That is where modern lift-assist devices come in.

"Workers might have to lift a 50-lb. (23-kg) part off a conveyor, pick it up and set it down, and they may have to do that a couple hundred times a day," said owner Mike Shannahan of Cynergy Ergonomics Inc. in St. Louis. "By the end of the day, that 50-lb. part feels like 200 lbs. (91 kg)."

He said a job could call for more than just lifting and lowering. Parts may need to be positioned for machining or other operations.

"You might need to load a CNC machine," Shannahan said. "The part may be light, but having to reach inside the machine and align it on the chuck several times a day can be a source of repetitive motion injuries."

Statistics bear that out. According to the National Safety Council, lifting is one of the main causes of injuries at workplaces. Every seven seconds, an employee is injured on the job. Of the workplace injuries that result in lost workdays, overexertion from lifting, lowering and repetitive motion makes up more than a third of such accidents.

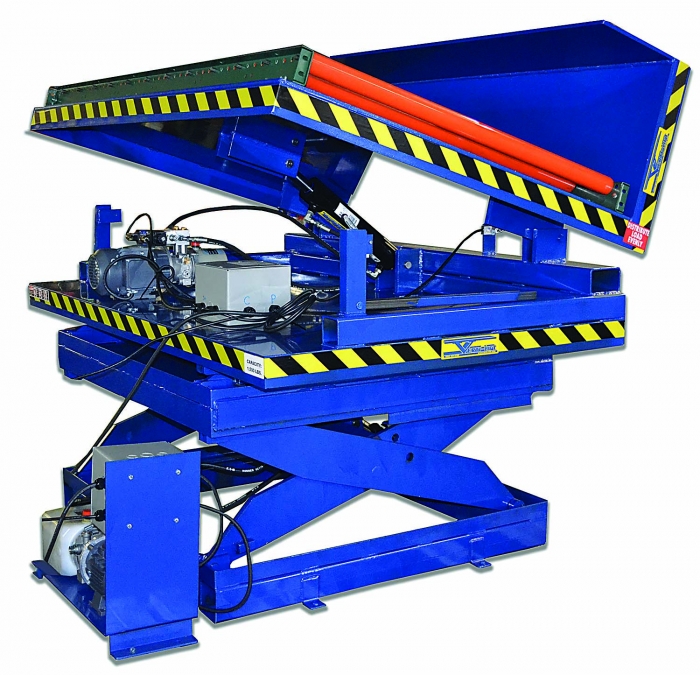

Lift-assist tables can be designed with a variety of conveying equipment. Image courtesy of Verti-Lift

"When it comes to moving lighter-weight or medium-weight items, such as 60-lb. (27-kg) boxes, injuries typically don't happen all at once," said National Sales Manager Bob DeBusk of Tawi USA Inc. in Bolingbrook, Illinois. "They happen over time. It starts to wear certain parts of a body. Then one day, the worker bends down to pick up a tissue and throws out their back."

Lift-assist devices can take the strain out of tasks by reducing overall weight and easing movement. Types of lifts include hydraulic, air, chain, crane and portable units. In addition to reducing workplace injuries, devices give workforce flexibility to company management, he said. A job that once took two people now might necessitate only one. Lifting requirements for employment also may change.

"A roll of material can weigh 100 lbs. (45 kg) and normally might take two people to do it, and you might still have injury issues," DeBusk said. With "lift devices, one person can do the job, and (this) allows management to hire from a larger pool of people. Workers that might normally not be able to physically lift these heavy and hard-to-handle loads can do so easily with a lift-assist device."

Customized to Fit

Lift equipment today is aided by new technology and a vast number of accessories to tailor a lift to an application. Shannahan said intelligent-assist devices from Cynergy Ergonomics, for example, feature a servodrive motor with a load cell and a programmable logic controller that communicate back and forth. The tools sense the movement of the hands holding them and adjust loads accordingly.

"If you just put a miniscule amount of lift force into those handles, it just lifts the part up," he said. "I can grab a 100-lb. part, and it will feel like it weighs a half a pound (0.2 kg)."

Because items to be moved vary so greatly, many lift-assist devices must be customized. For instance, a lift may be equipped with extending arms. At their ends might be customized suction feet, magnets, grippers, vacuums, probes or hooks. Cynergy Ergonomics utilizes a quick-change system that uses a pin to release and replace tooling in less than 10 seconds.

An extended handle is shown. Image courtesy of Tawi USA

Tawi USA is well tooled to modify its vacuum-lift technologies and other equipment to meet job requirements. Recently acquired by the Piab Group in Taby, Sweden, the company sells products through a distribution network. While the distributors are highly schooled in lifting technology, some jobs require deeper understanding. Tawi USA's vacuum-lift systems can be modified with a variety of accessories, such as top and bottom swivels that allow parts to be oriented as needed, turntables to bring parts nearer to workers or extended handles that prevent employees from having to bend over to reach the back of a pallet. The company has a team of engineers devoted to crafting solutions for job specifications. The solutions then can be developed in-house at Tawi USA's Chicago-area warehouse, fabrication shop and testing facility.

"Distributors come to us with an application," DeBusk said. "And we ask, 'What's the voltage? What's the capacity? What's the vertical travel? What's the size of the product that we are handling?' And then we begin to work with them to develop a lift system."

Putting It Together

Another common lift-device application is positioning parts and assemblies to make them easier and more ergonomic for assembly workers. As assemblies build up, personnel might need to raise or lower an assembly, tilt it on an angle or turn it toward them. A solution for this scenario is a scissor lift table like those offered by Verti-Lift Inc. in Louisville, Kentucky.

"Lift tables accomplish the ability to load and unload and handle material at an ergonomic, safe work height," said President Wayne A. Dodge. "And options, such as turntables, help orientate the part."

The company sells a variety of lift tables that can be modified based on standard products to fit applications — for example, enabling a standard table to lift, tilt and rotate parts.

"You've got standard lifts and accessories, such as tilt (tables) and turntables and conveyors, and independently they are just standard products," Dodge said. "But put together, you've got the ability to customize for specific applications."

Width and length are easily adjustable. Verti-Lift's standard tables, which can be used in various configurations, have vertical travel ranges from 610 mm (24") to 1,524 mm (60") and capacities from 907 kg (2,000 lbs.) to 2,722 kg (6,000 lbs.). A double-wide table is theoretically two scissor legs with one common platform and one common base. A tandem wall table is two lift tables front to back.

Dodge mentioned an electrical control panel assembly and its wide range of components and connections that require an operator to work at different heights at different locations on the board. Because this multilevel assembly crosses multiple axes, Verti-Lift developed a lift table that would lift, tilt and turn and that has a limitless range of motion.

An operator maneuvers a 113-kg (250-lb.) boiler from an assembly line to a pallet where the boiler is rotated 90°. Image courtesy of Cynergy Ergonomics

"With the lift, tilt and turn, you have an infinite range of travel vertically, horizontally and rotationally," he said. "You've got 360° of full rotation capability to the product, and in terms of tilt, the operator may start at (assembly) level and tilt it anywhere from zero to 90°."

By rotating a part, an operator can stay in one area and bring work to him or her, such as in a work cell.

"I like to think of that more as a product positioning versus simply raising and lowering," Dodge said.

Shannahan agrees that depending on the application, positioning can be critical.

"Let's say I need to put two halves of a die together," he said. "A 600-lb. (272-kg) half coming down on a bottom piece has to align to pins with very tight tolerances, and the positioning has to be spot on. That is why it is important that that 600-lb. part moves like it weighs 1 lb. (0.5 kg)."

Another example of positioning a product is with shipping, such as "This side up" packaging or for inventory control. DeBusk said Tawi USA's lift systems can include a top or bottom swivel that allows users to "spin" an item 360° while it is suspended in the air.

"So they can pick up a box, spin it for position and then place it on a pallet," he said. "Sometimes the customer needs the label facing out or in a particular direction, so their distribution center can bar-code-scan the item."

Holding the Position

In production, a part might need to be oriented at a specific angle. Cabinetmakers, for instance, often use panels that are 1 m × 2 m (4'×8') and weigh several hundred pounds. The sheets are shipped lying flat and must be stood vertically for machining with a vertical saw.

"We have an angle adapter that allows them to pick that up and move it 90° vertical and put it on (a) vertical saw in the position that they need," DeBusk said.

Positioning at such extreme orientations can be challenging.

"When we work with a customer," DeBusk said, "we collectively determine what they are handling, how they want to handle it, how their procedure or process works and how their employees do it. We develop a different strap, a clamping mechanism or an arm that will capture it to ensure safety and to ensure that the sheet is not damaged."

Uneven surfaces or porous materials can present challenges as well.

With these scenarios, Shannahan said, "It might be hard to pull a good vacuum. We address that by designing and building our own vacuum cups or designing the system to work around these contours or steps."

Tawi USA provides standard and custom suction feet to grip items, as well as rubber grommets that hold gaskets in place and allow feet to flex in any direction.

"So if one surface is at an angle and another surface is flat," DeBusk said, "then you can still pick it up."