Moldmakers tout benefits of aluminum molds for production

Moldmakers tout benefits of aluminum molds for production

The use of aluminum molds for production molding applications is the "biggest trend I'm seeing in moldmaking," said a longtime manufacturer of cutting tools.

The use of aluminum molds for production molding applications is the "biggest trend I'm seeing in moldmaking," said a longtime manufacturer of cutting tools.

Mike MacArthur, vice president of engineering at RobbJack Corp., Lincoln, Calif., described interest in aluminum molds as "huge" in the past year. "My sales leads have increased at least 10 times, and tool sales for aluminum moldmaking have increased six to eight times."

The president of Phoenix Proto Technologies LLC, Bob Lammon, echoed MacArthur's assessment. "There are a lot more suppliers and customers out there that recognize aluminum as a great benefit," said Lammon, whose Centreville, Mich., shop has been machining aluminum molds since the 1980s. He added that sales of aluminum and steel molds have risen in the past year, in step with the broader economy.

All images courtesy MSI Mold Builders.

Lammon conceded, however, that inquiries about aluminum remain mainly for prototype molds. "We're always trying to educate our customers on aluminum tooling," Lammon said, "how you can use it for many things and don't necessarily need steel. On the production side, though, that's where we have the biggest challenge."

MSI Mold Builders, Cedar Rapids, Iowa, and Greenville, S.C., designs and builds various types of steel and aluminum molds for a range of molding processes: injection, structural-foam and structural-web, rim, blow and gas-assist. Sales Manager Toby Bral said MSI also attempts to educate customers about their options.

"There is a mix of knowledge among customers," he said. "A lot of them, we're still educating. Some are coming to us and asking, 'We'd like to try this. Is this part a good application for aluminum? Do you have any concerns? Is this the way to go?'"

Bral noted that his company often experiments with aluminum prototypes before recommending them for production. He cited a customer for whom MSI created a heavy, high-quality aluminum prototype, which the customer then approved for short-term production. Bral said there is more interest in aluminum than there was 10 years ago, including production applications.

Market Factors

Mike Fecteau, senior applications engineer at machine tool builder Makino Inc., Mason, Ohio, said shorter production runs will drive demand for aluminum tooling.

And Andre Ey, vice president of die and mold technologies at Makino, said some automotive companies are already using aluminum for injection molding high volumes of select plastic parts.

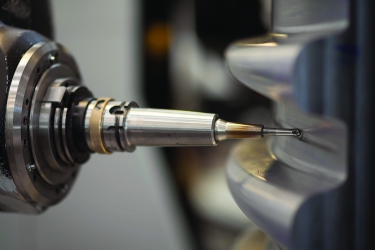

Aluminum is versatile and can be used for large and small molds alike. This large core insert is being cut on a 5-axis machine.

Ey said moldmakers that provide tooling from hardened steel are always looking to improve their efficiencies, as are their customers. He cited automotive companies as an example, adding that the varieties of models, face-lifts and trim changes have increased while production volumes for any one specific tool have decreased.

"Their costs are still the same to make that tool," Ey said, "but you don't make as many parts with that tool anymore." That means "the tooling cost has increased. So there is an incentive for automotive companies and tool and die companies to figure out how to make tooling cheaper."

Enter aluminum.

The historical desirability of the metal for some shorter production runs fits nicely with the modern motivation for lean manufacturing, according to MacArthur and Bral. An order that in past years would have been for 500,000 parts now may be an order for only a fraction of that number.

"People don't want to have large warehouses of inventory anymore," MacArthur said. "Product development and everything else are going a lot faster now. The whole cycle has shortened quite a bit."

"There are more pricing pressures," Bral said, "and molds are turning over quicker too. People are asking themselves how they can compete."

MacArthur acknowledged that aluminum is softer and wears quicker than steel. However, shorter life cycles for products make aluminum more attractive, along with its lower cost and its ability to be machined faster.

Bill Stickley, general manager of Michiana Global Mold, a moldmaking company in Mishawaka, Ind., agreed. "Aluminum is so much faster and easier to machine than steel is," he said. "That's one of the reasons you would use aluminum."

Applications and Predictions

Phoenix Proto Technologies' Lammon said even for longer production runs, aluminum can sometimes be substituted for steel. For instance, he can "hard-coat" aluminum to add durability and to slow wear.

The combination of ever-improving technology and increasing interest in aluminum from customers has brought new competition.

"There are more players in the aluminum tooling industry in the past year or two," Lammon said.

Operators load a large aluminum mold cavity onto a CNC machine.

Phoenix had about a 10 percent rise in orders late last year, with the percentage of inquiries being even higher. Lammon said such a difference is normal, and he expects a greater increase in orders as prospective customers finish evaluating their options for manufacturing parts. The element of secrecy also plays a role in the market.

"We have situations where customers try aluminum," Lammon said, "and they're, like, 'Wow, this is more valuable than we anticipated.' " However, quite a few Phoenix customers request that the moldmaker keep confidential that it's producing aluminum tooling for them. "A great deal of it is that people don't want their competition to use the same process. So they don't talk about how good aluminum is," said Lammon.

MSI Mold Builders has positioned aluminum as a wise choice for many years, especially for low- and medium-volume jobs.

Bral said possibilities open up even more because of the advent of hybrid molds, which are made from steel and aluminum. Hybrid molds lower costs and lessen manufacturing time. He cited a highly polished surface, such as the outward-facing hood or fender of an automobile, as an example. That surface can be made from steel while other surfaces can be made from aluminum.

"The visual stuff looks good polishwise," he said. "The nonvisual side doesn't matter. The back side of parts is what we find typically drives cycle time the most. It's hard to get good water and cooling into the crevasses and recesses in the back side. There are heavy structures there that are difficult to cool. Aluminum's thermal conductivity helps cool the part so much better back there."

Aluminum is in a good position for the future of moldmaking, according to Lammon. "People are always looking for better ways. Faster, leaner, more economical."

Bral agreed and cannot envision demand reversing."I don't see it decreasing," he said. "I would think it would only increase due to the trends—especially in the automotive world—of more and more molds," each of which is used to produce fewer parts. "Also, as you lower your plastic parts' cost through aluminum, that helps offset competition from additive manufacturing. The market is still heavily driven by steel, no doubt, but there are more and more opportunities for aluminum."