Sizing up software

Sizing up software

Spotting and dealing with CAD/CAM issues is crucial to manufacturing success.

Like every other piece of a modern production process, manufacturing software should be checked on a regular basis. Among other things, these checks help ensure that the software is functioning properly and meeting the manufacturer's current business needs. In addition to checking their CAD/CAM software, shops can use other software tools to check part-making programs to catch potential problems before manufacturing actually kicks off.

In many production settings, CAD/CAM gets a thorough check during periodic software audits. When performed by a manufacturing firm, such an audit is "a pretty comprehensive process," noted Ke Wang, applications engineering manager at Mastercam, a CAD/CAM developer in Tolland, Connecticut. According to Wang, a software audit includes input from users who report on matters such as their level of satisfaction with the software, any defects they have discovered and additional software features that they think would be helpful. In addition, he said, the company's IT team evaluates the security, compatibility and scalability of the software, while the financial team looks at the impact of the software on the company's fiscal health.

Software monitoring should be part of the regular routine of a manufacturing business. Image courtesy of Mastercam

As to the timing of CAD/CAM audits, Wang said many small- to medium-sized manufacturing companies perform them every year to coincide with typical software release cycles. But he added that some larger and more complex companies, as well as those that are growing fast or making rapid technological advancements, need more frequent audits—perhaps twice a year or every quarter. In addition, he pointed out that some audits are event-driven. Events that can trigger a CAD/CAM audit include the acquisition of new CNC equipment and the addition of a new product line. Major operational changes like these may create a need for CAD/CAM features that are lacking in the company's existing software package.

Continuous Monitoring

Formal audits aside, Wang noted that software monitoring should be a continuous effort and part of the regular routine of a business. This task includes staying on top of matters such as whether key performance requirements are being met and whether any CAD/CAM-specific issues are causing safety problems. It also includes maintaining adequate software security and access control—for example, by keeping up-to-date on personnel additions and departures. "All those things have to be checked on a weekly or even a daily basis," he said.

In addition, effective CAD/CAM monitoring requires users to keep alert for — and respond to — telltale signs that a software check is needed. For example, Wang said, the software might be crashing frequently or operating too slowly.

Then there are situations where something is clearly wrong, but it is unclear whether software is causing the problem. "When you have an unsatisfactory result in your CNC manufacturing process, there are lots of moving pieces: software, programming, tooling, whether or not the correct toolpath is used," Wang said. "All these can play a major role in the result. And all these require the programmer or the technical team to make an educated assessment of the issue."

According to Wang, an experienced programmer or technical team should be able to identify the problem immediately and also determine whether it's caused by software or another part of the manufacturing process. "But if you have someone out of college last month trying to do the same thing, that (person) probably needs lots of handholding." he said. In cases like this, he said, help is available from the software developer or reseller.

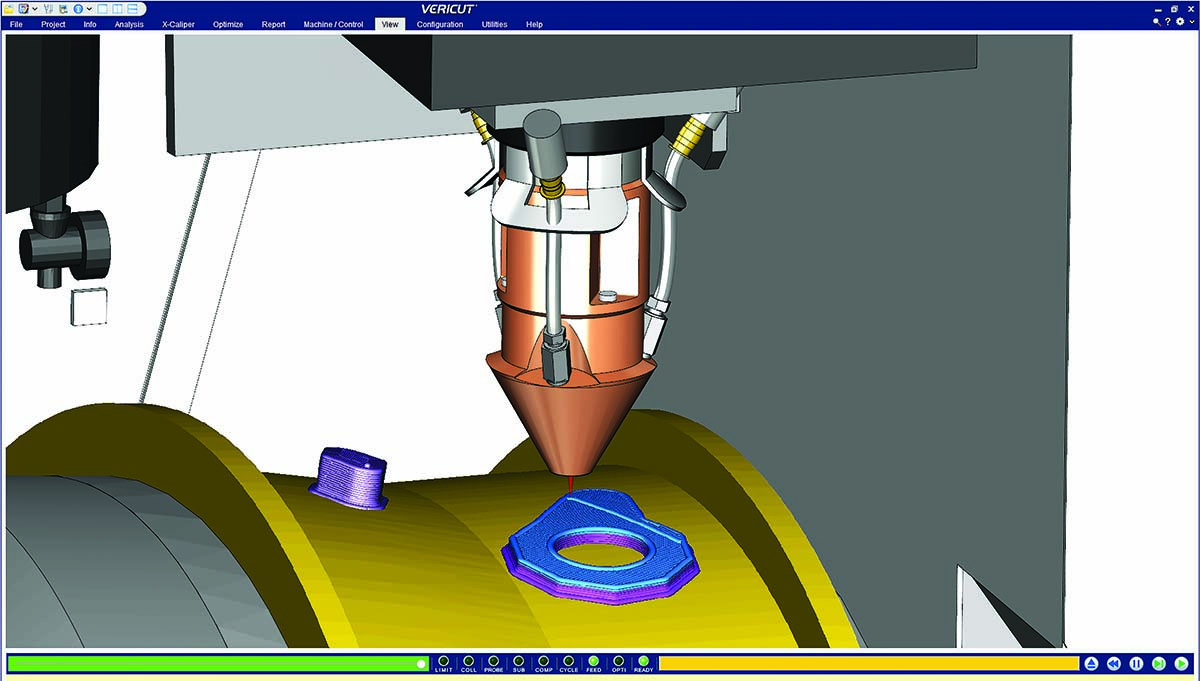

Vericut software can be used to check both machining and additive manufacturing processes. Image courtesy of CGTech

If it is determined that Mastercam software is causing a manufacturing problem, Wang said the first step is for the company to help the customer come up with a temporary workaround so that production can resume. "We will probably suggest a different approach, (such as) a different toolpath to cut a part or a different use of a tool," he said. "Sometimes it's less efficient, but it can get the customer through the current job."

In the meantime, Mastercam will take a closer look at the problem. "Our internal process will kick in to find out if we need to make an improvement or feature change," Wang said. "If that becomes a reality, we will publish a service pack or update of the software to address the issue." On a quarterly basis, he added, the company releases software updates to address problems reported by customers. In addition, these problems are fixed in the new versions of the software that are released each year.

In general, however, Wang reported that in his experience, 90% or more of the software issues experienced by Mastercam customers can be traced back to improper use of the software and/or inadequate software training. So he stressed the importance of good initial training, as well as periodic, continuous learning about the software. For a CAD/CAM package, he said, training should be done by the software developer or reseller, or by a professional trainer.

Simulation Solution

Besides issues related to the CAD/CAM software itself, manufacturing processes can be adversely impacted by faulty machining programs created by users of the software. When cutting commences, so-called "fat finger" errors and other program flaws can cause unwanted contact between various components inside the machine, resulting in costly damage.

Thus, the desire to simulate programmed cutting routines in a virtual environment before the actual machining begins. "CAM software people tell you that they have a way to check their programs" prior to the start of real machining, noted Ely Wahbeh, Vericut product manager at CGTech, a software developer in Irvine, California. "But the issue there is the programs are simulated before they get post-processed."

Software developers can help customers identify and solve CAD/CAM problems. Image courtesy of Mastercam

Post-processor software translates CAM toolpaths into Geometric code, or G-code, for a specific CNC machine. Since the verification tools offered by typical CAM systems simulate programmed cutting routines before they're converted into G-code, Wahbeh said, they can miss collisions and other program-related problems that crop up during the actual machining processes.

That's why there's demand in the machining industry for software like CGTech's Vericut. Capable of integrating with all major CAM systems, Vericut can simulate a variety of CNC machine tools from leading manufacturers. The software checks a programmed cutting routine by running the G-code on a digital twin of the machine that will make the parts.

"You get to see a part cut virtually," Wahbeh said. "If everything looks great, you're good to go," Wahbeh said. "If there is a problem, you can see where the collision [occurs] and which section of the program is causing that problem. Then you can go back into your CAM system and work on it."

Discovering machining problems at this early stage is far better than discovering them later on. "It's easier to recover virtually than it is from a real [problem] on the shop floor," Wahbeh said. At that point, "there could be a lot of damage to the tools, spindles, fixturing, you name it."

Besides simulating subtractive manufacturing, Vericut can be used to check metal deposition processes performed by 3D printers and hybrid additive-subtractive machines. As Vericut does with machining, the software's additive module uses the same G-code file that will be used to drive the real production process so the simulation will match the actual machine behavior as closely as possible.

A brand new capability offered by Vericut version 9.4 is a CNC Precheck application, which can be used on shop floor computers or Windows tablets next to CNC machines. The application connects to machines to compare setup information in the machine to the corresponding settings in the Vericut simulation.

According to Wahbeh, verifying that these settings match as closely as possible is another way the software helps users breathe easier when it's time to push the cycle-start button to initiate real machining. With the CNC Precheck application added to traditional Vericut, "you get a check from the CAM side and a check from the live machine side," he said. "And by doing these two checks, your confidence level goes much higher."