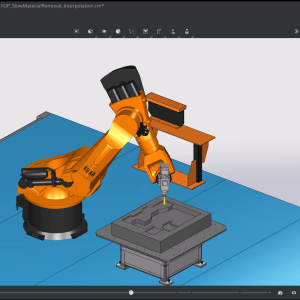

Automation Systems

Robots set a healthy pace in 2022

While aircraft and automotive sales may be languishing due to supply chain constraints, that’s not the case in the automation industry. For three consecutive quarters, North American robot sales have hit record highs, according to the Association for Advancing Automation in Ann Arbor, Michigan. For CNC machining in particular, orders for automation are “beyond expectations,” said Craig Zoberis, founder and president of Burr Ridge, Illinois-based Fusion | RoboJob-USA, which provides systems for automatically loading and unloading CNC turning and milling machines.

IMTS 2022 Booth Visit with Rollomatic

Rollomatic SA Chief Product Officer Gert-Jan Hartog shows off the company's smart factory concept featuring a collaborative robot and a smart mobile manipulator, an automated guided vehicle equipped with a six-axis collaborative robot on top.

Click here to visit Rollomatic's website.

IMTS 2022 Booth Visit with GF Machining Solutions-System 3R

John Roskos, GF Machining Solution’s regional sales manager for System 3R, shows off the System 3R WorkPartner 1+ automation cell during IMTS 2022.

Click here to visit System 3R's website.