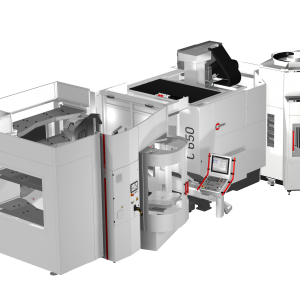

Automation

Keeping steel wheels spinning

Since 1910, Simmons Machine Tool Corp., Albany, New York, has built machine tools and measuring machines for producing and maintaining railway wheel sets. The company also manufactures automation systems.

Each wheel traditionally is placed on a machining center using a forklift, a crane or another manual handling method — a slow, inconsistent process in which worker safety is a concern. Simmons Machine Tool sought to boost productivity and improve worker safety when loading and unloading railways for repairs in a vertical CNC lathe.

Presenting an automated coolant delivery system

Precision Tool Technologies Inc., Brainerd, Minnesota, developed the FullShop automated coolant delivery system to eliminate manually monitoring and replenishing coolant so that the shop could enable unattended machining. This video, presented as a video supplement to CTE's May 2020 Productive Times article, offers a quick overview of the company's FullShop system, which monitors coolant usage at a machine tool sump and automatically replenishes coolant before it runs low.