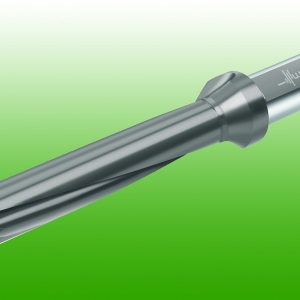

Learn How IC Drills Help Conquer More Difficult Drilling Dilemmas

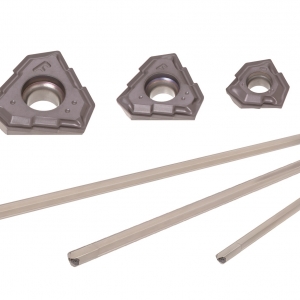

Why do indexable carbide drills excel in more extreme drilling applications? To find out, watch Allied’s senior product manager and engineering trainer team up to demonstrate.

Difficult drilling applications in this educational, 5-minute clip include: