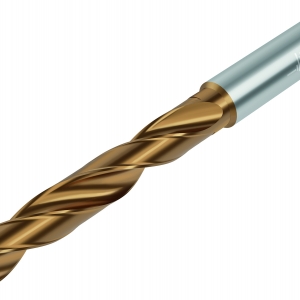

Drills

A Brand ADO-SUS: Coolant-Through Carbide Drills

Work hardening, welding, elongation of cutting chips and poor thermal conductivity are common problems when machining stainless steels and titanium alloys. OSG’s A Brand® ADO-SUS drill series is designed to excel in these materials. ADO-SUS’s "Mega Cooler™" coolant hole shape improves coolant flow and chip evacuation while reducing heat generation; this reduces work hardening and results in longer tool life. ADO-SUS also features OSG’s proprietary WXL® coating for improved wear resistance.

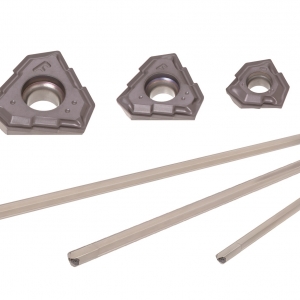

Learn How IC Drills Help Conquer More Difficult Drilling Dilemmas

Why do indexable carbide drills excel in more extreme drilling applications? To find out, watch Allied’s senior product manager and engineering trainer team up to demonstrate.

Difficult drilling applications in this educational, 5-minute clip include:

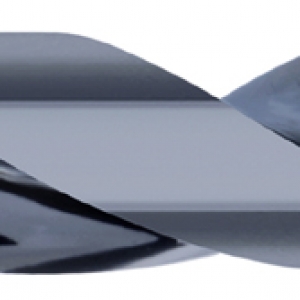

The New Edge In Aluminum Alloys

Video highlights special features of the IMCO POW•R•PATH AP5 Series, including a revolutionary 5-flute design for HEM tool paths in aluminum alloys, and a solid core and extra durable coating for maximum tool life. Available with CMS for maximum chip control, the POW•R•PATH AP5 Series also offers high metal removal rates for extreme productivity.

For more information visit us at http://www.imcousa.com/